Dash cams are now common across trucking fleets, mine sites, and people-transport operations. They help reconstruct incidents, settle claims, and coach operators. But nearly every safety manager has faced the same moment:

A haul truck has a near-miss.

A pickup carrying contractors drifts in the early morning.

A bus transporting workers brakes hard on a downhill grade.

Everyone rushes to review the footage, but by then, the risk already materialized.

Cameras react. They do not predict.

Whether it’s a Class 8 tractor on a highway, a 240-ton haul truck on a ramp, or a people-transport vehicle navigating rough mine roads, reactive tools only tell you what happened after the danger has already escalated.

KEY TAKEAWAYS

-

Most fleets and mines still rely on reactive safety systems like dash cams that only capture events after risk has already developed.

-

Reactive tools support claims and investigations but do little to prevent serious incidents, including haul-truck collisions and people-transport vehicle rollovers.

-

A proactive safety strategy helps both transportation fleets and mining operations identify and reduce risk earlier in the day.

-

Predictive fatigue management is often the missing upstream indicator that dash cams cannot provide.

-

Readi enables fleets and mining operations to shift toward proactive safety by forecasting fatigue risk before the shift begins.

The Reactive Dash Cam Safety Strategy (The Old Way)

1. You review footage after the collision or near-miss

Useful for investigations, but the event already happened. Equipment is damaged, production slows, and the root cause remains unaddressed.

2. You flag harsh events after instability occurred

Harsh braking in a haul truck. Cornering too fast in a light vehicle. A drift on a night-shift highway run. Telematics tells you only after the moment of danger.

3. You coach operators based on history

Coaching might be solid, but it occurs days laterm disconnected from the moment that matters.

This reactive loop is the same whether the vehicle weighs 80,000 lbs or 400 tons.

Why Fleets and Mines Are Moving to a Proactive Safety Strategy

Safety leaders in both industries are looking for upstream signals that allow intervention long before a camera would ever trigger an alert.

Proactive safety shifts the conversation from:

“What went wrong?” to “What can we prevent tomorrow?”

This approach:

-

Reduces catastrophic haul-truck incidents

-

Improves people-transport safety

-

Protects night-shift haul drivers

-

Supports shift planning and workforce management

Most importantly, proactive safety allows teams to coach, adjust, and intervene before the operator is in trouble.

What Proactive Safety Looks Like in Practice

1. Detect risk early instead of reacting late

Drivers, haul-truck operators, and transport crews receive early-warning signals that help them avoid unsafe scenarios.

2. Coach or intervene in the moment

Real-time insights let supervisors support operators before a risky behavior turns into a critical event.

3. Monitor unsafe patterns before they escalate

Fatigue spikes, distraction patterns, and circadian misalignment become visible in daily planning.

4. Address human factors, not just mechanical inputs

Camera alerts show driver behavior.

Fatigue insights show why the behavior occurred.

This combination is what modern fleets and mines need.

The Missing Piece: Predictive Fatigue Management

Fatigue is the root cause behind many behaviors that dash cams capture:

-

Late braking

-

Wandering lanes

-

Poor judgment underground

-

Slow reaction time at intersections

-

Microsleeps on long haul roads

-

Inconsistent speed control

-

Reduced awareness during early-morning personnel transport

In mining, this can be catastrophic. In trucking, it can be fatal.

Dash cams can’t forecast fatigue. HOS compliance can’t guarantee rest.

Fatigue is invisible, unless you predict it.

Predictive Fatigue Management Complements Dash Cams

Predictive fatigue tools help supervisors see which drivers and operators are most likely to experience low alertness during their shift, whether they are:

-

A haul-truck operator on a 12-hour night shift

-

A haul driver running an early-morning departure

-

A people-transport shuttle driver rotating crews underground

-

A fuel-truck operator servicing a remote pit

-

A regional freight driver navigating high-traffic corridors

This lets teams make adjustments early:

-

Reassign a particularly high-risk task

-

Time breaks to match fatigue windows

-

Avoid scheduling critical tasks during predicted low-alertness periods

-

Review chronic fatigue patterns for long-term schedule redesign

This is what it means to shape what happens next, not just document what happened.

Where Readi Fits Into Proactive Safety for Both Fleets and Mines

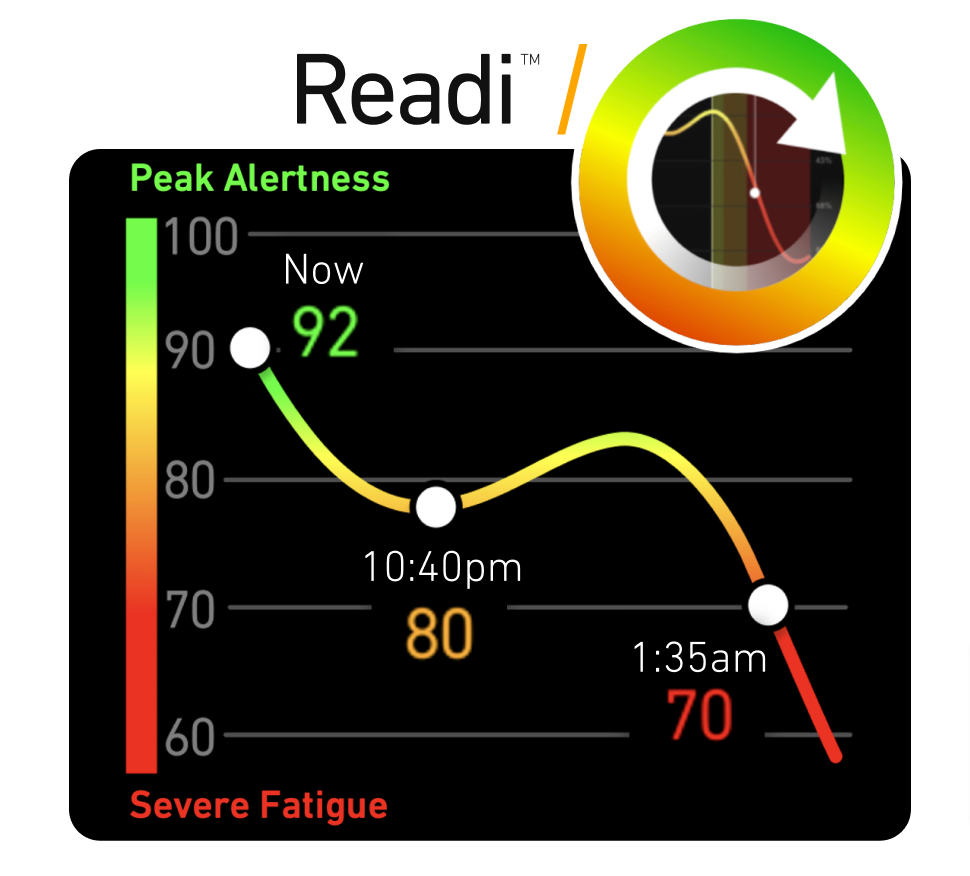

Readi brings predictive fatigue management into everyday operations by:

-

Providing personalized, hour-by-hour fatigue predictions for every driver or operator

-

Identifying high-risk windows before the shift begins

-

Giving dispatchers, supervisors, and control-room teams actionable insights

-

Offering documented intervention logs for audits, insurers, and regulators

-

Supporting both surface and underground operations without hardware or connectivity requirements

Whether your risk is a highway rear-end collision or a haul-truck drift on a downhill ramp, Readi gives visibility into the human factors that cause the toughest, costliest events.

Dash cams show you the moment. Readi helps you prevent the moment.

FAQ

Do dash cams still matter if you use predictive fatigue management?

Yes. Dash cams remain essential. Predictive fatigue management adds upstream visibility that dash cams alone cannot provide.

Does predictive fatigue management help with haul trucks and mining vehicles?

Absolutely. Haul-truck fatigue is one of the most documented high-risk categories in mining. Predictive tools give mine supervisors visibility long before an operator sits in the cab.

Can predictive fatigue insights be used for people-transport and shuttle drivers?

Yes. People-transport operations often run early mornings, late nights, and long commutes, all prime fatigue conditions. Predictive insights help reduce rollover, drift, and reaction-time events.

Is Readi intrusive for operators?

No. Readi operates without wearable requirements and uses shift, schedule, and rest opportunity data to provide predictions while respecting privacy.

Does predictive fatigue management improve insurance positioning?

Insurers increasingly reward fleets and mines that can demonstrate proactive safety controls. Predicting and documenting fatigue risk strengthens renewal negotiations.

Related Posts

-

Can You Predict Fatigue Risk in Mining Without Wearables? New Research on Survey-Based Deep Learning Techniques for Measuring Fatigue Says YesFatigue is one of the biggest safety and performance risks in mining operations and other heavy industries. Workers who are tired...

-

An Interview with International Mining Magazine: A New Approach to Fatigue Management in MiningMining safety has always relied on layers of protection. What’s changing now is where those layers start.

-

Top AI Trends for Fleets in 2026The trucking industry is entering a new phase of digital maturity. What began as basic telematics and compliance automation is...