In 24/7 mining and industrial fleet operations, fatigue is a high-frequency, high-cost risk multiplier. Historically, organizations have relied on lagging indicators like wearables, schedule templates, or subjective sleep reporting to manage fatigue. But today, forward-looking health and safety leaders are asking a better question: "What if you could predict fatigue risk before the shift even starts without hardware, tracking, or human guesswork?"

Welcome to the future of fatigue risk: AI-powered, non-wearable, software-only fatigue prediction that’s validated by science, built for scale, and already making a measurable impact across global mining and fleet operations.

From Reactive to Predictive Fatigue Management

| Challenge | Old Approach | Modern Approach (with Readi) |

|---|---|---|

| Incomplete data | Last night's sleep or self-reporting | 10-day predictive fatigue model using schedule + ML |

| Hardware fatigue | Wearables, sensors, costly devices | No hardware required, privacy-first |

| Low scalability | Difficult deployment across remote sites | Seamless software deployment across regions |

| Limited insight | Group-level or generic risk modeling | Personalized ReadiScores for every operator |

| Reactive supervision | In-shift fatigue correction | Pre-shift fatigue prevention, up to 18 hours ahead |

Why Traditional Fatigue Methods Fall Short in High-Risk Operations

For decades, mining and heavy transport fleets have leaned on four legacy tools to monitor and mitigate fatigue:

-

Static schedule-based assessments

-

Wearable devices (e.g., wristbands, EEG headbands)

-

Manual self-reports or supervisor gut feel

-

Cameras and reactive alerting systems

Each has limitations:

-

Wearables often face union resistance, break, or go unworn.

-

Self-reporting is subjective and inconsistent.

-

Camera systems only trigger after fatigue becomes visible.

-

Schedule analysis doesn’t account for individual variability in sleep need or recovery.

“Most HSE teams are still managing fatigue like it’s 2005. But the truth is, you can’t ‘spot check’ your way to real safety,” says Solange Messier at Fatigue Science. “You need to know who’s at risk, when they’ll be impaired, and how to act before it happens.”

Modern Fatigue Management: Software, Not Hardware

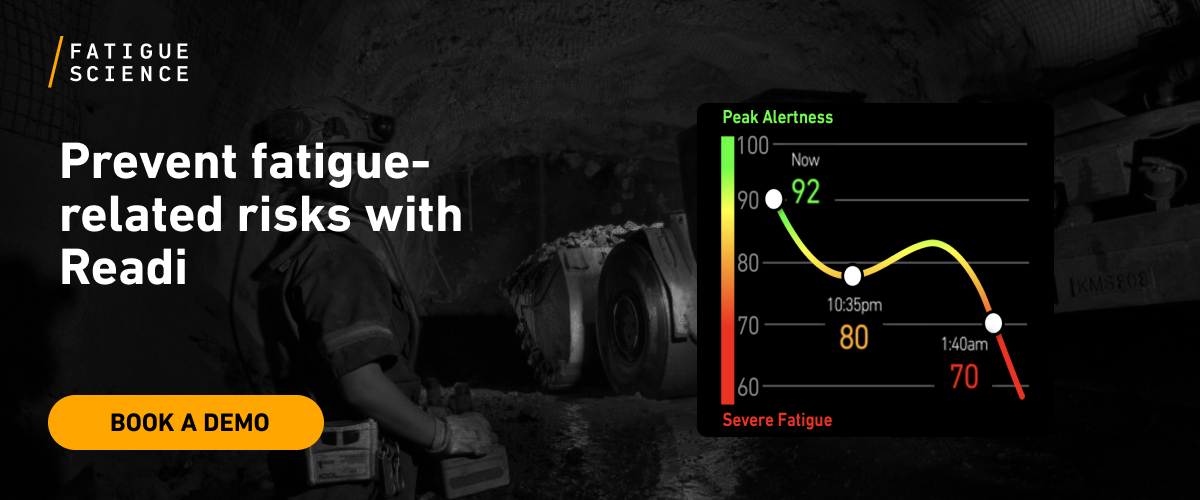

The next wave of fatigue risk solutions (like Readi, built by Fatigue Science) is built on predictive analytics and eliminates the need for wearables.

Here’s how it works:

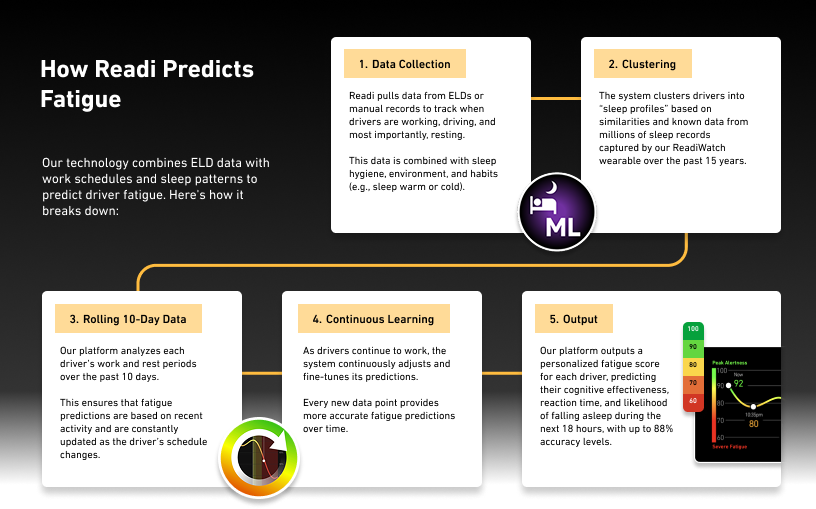

1. AI Gap-Filling for Incomplete Data

If a worker didn’t wear a device (or no device was issued) Readi uses AI models trained on over 10 million nights of industrial sleep data to fill in the gaps based on shift schedule, job role, and optional survey inputs.

2. Unique Sleep Profiles for Every Operator

Readi builds individualized fatigue models that reflect how each operator uniquely responds to shift work, sleep opportunities, and environmental demands. These power the ReadiScore, an hour-by-hour prediction of fatigue risk.

3. Circadian Rhythm Integration

Night shifts, variable rotations, and fly-in/fly-out schedules all impact fatigue. Readi integrates circadian science to model when operators are likely to hit critical fatigue thresholds.

4. Automated Schedule Ingestion

Readi reads crew schedules from HR, T&A, or dispatch systems. The platform models optimal rest windows and flags conflicts or cumulative risk by shift, by operator.

5. Validated Against 10M+ Sleep Records

Unlike black-box AI, Readi’s outputs are continuously validated using a proprietary sleep dataset, making its fatigue predictions scientifically trustworthy and operationally practical.

“We’re not just predicting fatigue. We’re giving HSE teams the tools to manage it like a process, not a surprise,” adds Messier. “That’s a shift in mindset, and it’s saving lives.”

Key Benefits of Readi for Mining and Fleet Operations

| Feature | Impact on Safety and Productivity |

|---|---|

| 18–30 hour fatigue forecasts | Enables pre-shift mitigation, not just in-shift corrections |

| No wearables required | Higher adoption, fewer privacy objections |

| Personalized predictions | Reduces false positives and one-size-fits-all protocols |

| Circadian-aware modeling | Especially critical for night shift and rotational crews |

| Live insights for supervisors | Instant go/no-go decisions and crew-level risk sorting |

Unlike reactive systems (e.g., in-cab cameras or impairment tests), Readi gives teams lead time to act before impairment leads to errors, injuries, or equipment damage.

Deployment: Simple, Fast, and Scalable

You don’t need to overhaul your tech stack to modernize fatigue risk.

To deploy Readi’s non-wearable model, all you need is:

-

Access to operator shift schedules

-

Optional one-time operator sleep survey

-

Dispatch or supervisor training (1–2 sessions)

-

Buy-in to take fatigue scores into shift-start planning

Frequently Asked Questions

Q: Is non-wearable fatigue monitoring less accurate?

Readi’s predictions are around 90% as accurate as a wearable. They are validated against millions of real-world sleep records and follow the SAFTE™ model, which is used by NASA, FAA, and military operations.

Q: Does Readi replace wearables or camera systems?

Not necessarily. It’s often used as a predictive layer alongside camera or reactive tools, helping reduce false positives and triage alerts more effectively.

Q: How do workers react to this system?

Most crews prefer Readi over being tracked or filmed. It doesn’t collect biometric data, doesn’t monitor in real time, and is privacy-compliant, which is critical for union environments.

The Future of Fatigue Is Predictive, Personalized, and Hardware-Free

In the past, managing fatigue meant wearables, forms, or best guesses. But today, mining and fleet operations can see fatigue coming days before it affects the field.

Readi gives HSE teams the predictive insight, supervisor tools, and personalized data they need to cut risk before it becomes cost. No hardware. No invasive tracking. Just the science of sleep, turned into action.

“The best fatigue management strategy is the one your team will actually use,” concludes Messier. “With Readi, that means smarter shifts, safer crews, and fewer surprises.”

Ready to modernize fatigue risk in your operation? Let’s talk about your pilot.

Related Posts

-

Can You Predict Fatigue Risk in Mining Without Wearables? New Research on Survey-Based Deep Learning Techniques for Measuring Fatigue Says YesFatigue is one of the biggest safety and performance risks in mining operations and other heavy industries. Workers who are tired...

-

An Interview with International Mining Magazine: A New Approach to Fatigue Management in MiningMining safety has always relied on layers of protection. What’s changing now is where those layers start.

-

Shifting From Reactive Dash Cam Safety to a Proactive Safety StrategyDash cams are now common across trucking fleets, mine sites, and people-transport operations. They help reconstruct incidents,...