How AI Is Shaping the Future of Occupational Health

How AI is Shaping the Future of Occupational Health

Summary

-

AI in occupational health is revolutionizing workplace safety by enabling predictive, data-driven strategies.

-

Real-time health monitoring, predictive risk assessment, and automated hazard detection are the core applications.

-

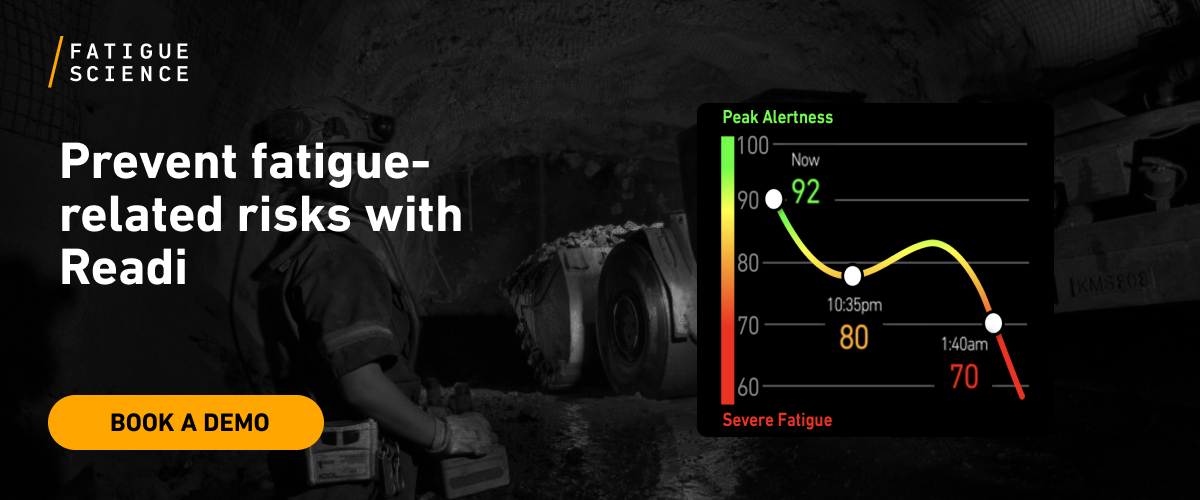

Readi by Fatigue Science exemplifies best-in-class predictive fatigue management using AI without wearables.

-

AI use cases in heavy industry extend beyond fatigue, covering ergonomics, heat stress, chemical exposure, predictive maintenance, and mental health.

-

Benefits include reduced incident rates, improved productivity, lower costs, and streamlined compliance.

-

Organizations must address privacy, technical integration, and change management to implement AI successfully.

-

The future of occupational health lies in full-scale integration of AI across all aspects of workforce management.

What is AI in Occupational Health?

AI in occupational health refers to the integration of artificial intelligence, including machine learning, predictive analytics, and intelligent systems, to improve workplace safety and employee well-being. Unlike traditional reactive approaches, AI enables proactive identification and mitigation of health risks before they lead to incidents.

AI-driven systems can:

-

Monitor workers in real time using biometric and environmental data.

-

Forecast potential health and safety risks based on historical patterns.

-

Enable personalized health and fatigue insights without invasive tools.

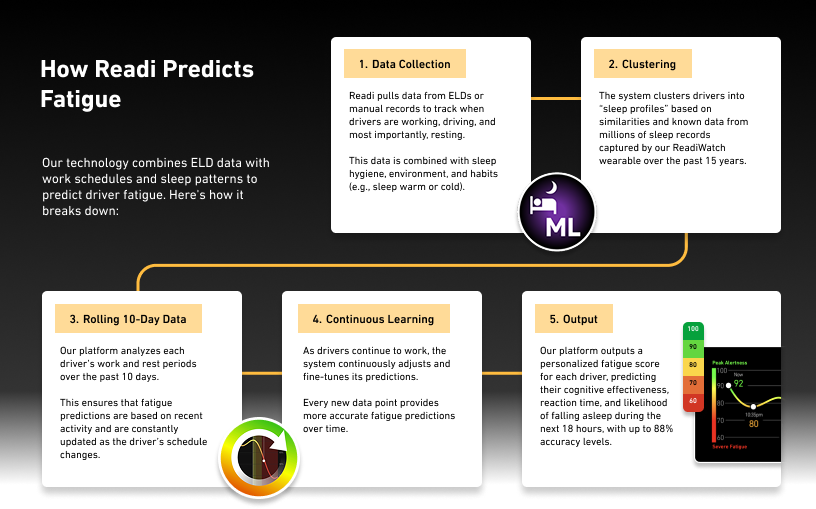

For instance, Readi by Fatigue Science uses machine learning to generate predictive fatigue scores (ReadiScores) for every worker based on their sleep data, shift schedules, and circadian rhythms. These scores are available up to 18 hours in advance, helping supervisors take action before risk escalates.

According to the ILO and NIOSH, over 2.78 million workers die each year from occupational accidents or work-related diseases. AI adoption in health and safety systems can reduce workplace injuries by up to 30% through predictive analytics (source: NIOSH, 2023).

How Does AI Transform Traditional Safety Management?

Traditional safety programs operate on lagging indicators:

-

Incident reports filed after an event.

-

Manual checklists and self-reporting.

-

Generic training and compliance-focused protocols.

AI flips the model to leading indicators:

-

Real-time risk alerts based on current conditions.

-

Personalized risk profiles based on individual behavior and sleep history.

-

Continuous feedback loops to optimize interventions.

Key transformations:

-

From reactive to predictive: Instead of reacting after a near-miss or injury, AI predicts when risk is likely to occur.

-

From generic to personalized: AI systems like Readi model fatigue risk per individual, hour-by-hour.

-

From snapshots to continuous monitoring: Every shift is monitored for emerging trends, not just periodic assessments.

Real-Time Health Monitoring

In logistics and utility sectors where long shifts and distributed operations are common, real-time monitoring helps maintain operational awareness across crews and time zones.

-

Wearables & Non-Invasive Monitoring: Devices like the ReadiWatch (or integrations with Garmin and Fitbit) track sleep quality, movement, and environmental conditions. AI interprets this data to deliver fatigue predictions.

-

Environmental Sensors: Smart sensors monitor noise, air quality, temperature, and more.

-

Worker Dashboards: Platforms like Readi display real-time ReadiScores, helping supervisors identify when and where risks may arise.

-

Heat Stress Detection: AI combines internal and external temperature data to warn of dangerous heat exposure levels.

Predictive Risk Assessment

-

Fatigue Forecasting: Machine learning models like Readi's SleepML predict future fatigue levels using historical sleep and schedule data.

-

Risk Heatmaps: AI visualizes risk levels across job sites and teams, enabling targeted countermeasures. This is especially valuable in mining environments with remote shift operations and long work hours.

-

Ergonomic Analysis: AI analyzes motion patterns to detect overuse or incorrect posture before musculoskeletal disorders develop. Utilities and warehouse sectors benefit from this through lower strain-related downtime.

-

Mental Health Prediction: Early warning systems monitor stress levels based on digital behavior, speech tone, or wearable data.

Automated Hazard Detection

-

Computer Vision: AI systems analyze video feeds to flag unsafe behaviors like missing PPE or operating while drowsy. In oil & gas, this complements existing camera-based safety tools.

-

Smart PPE: Embedded sensors detect hazardous exposure and alert workers.

-

Predictive Maintenance: AI models predict equipment failures before they occur, preventing downtime and injuries.

Monitor Repetitive Motion to Reduce Ergonomic Injuries

In mining and utilities, repetitive use of heavy tools, crouched positions, and awkward lifting are leading causes of musculoskeletal injuries.

AI-powered ergonomics monitoring uses computer vision, wearable sensors, and biomechanical analysis to identify risk factors before injuries develop. Systems track posture, load strain, and motion frequency throughout shifts.

By alerting supervisors to trends in real time, these systems enable early interventions—such as rotation schedules or equipment redesign. Predictive analytics allow companies to prioritize ergonomic improvements where risk is highest.

Use case: In logistics warehouses using AI ergonomic monitoring, one company reported a 42% reduction in back injuries within 12 months (source: OSHA/NASP study, 2024).

Detect and Prevent Heat Stress Using Body Temperature and Environmental Data

In oil & gas, construction, and open-pit mining, workers are often exposed to high heat for long durations. AI helps monitor and prevent heat-related illnesses before they escalate.

Wearable sensors track temperature, hydration status, and heart rate. Environmental sensors capture external heat and humidity. AI algorithms fuse this data to calculate individual heat risk levels.

When thresholds are breached, alerts notify supervisors in real time. Workers may be instructed to hydrate, rotate out, or move to shaded zones.

Alert Workers to Chemical Exposure Risks in Real Time

In chemical plants, mining operations, and refineries, exposure to airborne toxins is a daily risk. AI-driven sensor systems now provide real-time alerts to avoid overexposure.

Wearable badges or helmet-mounted sensors detect concentrations of harmful substances like VOCs, CO2, or dust. AI compares exposure levels against OSHA limits and triggers automatic alerts.

Monitor Mental Health Signals Through Biometric and Behavioral Patterns

Logistics drivers, utility technicians, and isolated workers in remote mines face intense mental health demands. AI identifies early indicators of burnout, stress, or cognitive fatigue.

Inputs include heart rate variability, sleep disruption, keyboard typing speed, or even sentiment in voice tone. These signals are anonymized and analyzed for trends.

What Benefits Does AI Bring to Occupational Health Programs?

Enhanced Safety Outcomes

AI enhances safety outcomes by transforming hazard identification and intervention timing. Instead of waiting for an injury or incident to trigger a review, AI-powered platforms like Readi provide real-time predictive insights based on physiological, environmental, and behavioral data. These systems flag fatigue risk, heat stress potential, unsafe behaviors, or equipment malfunction before they escalate into incidents.

In industries like mining or logistics, AI enables proactive decision-making hours or even days in advance. For example, predictive fatigue management can reduce microsleeps and cognitive lapses during critical tasks such as haul truck driving or crane operation. According to Readi case studies and ILO research, organizations using predictive tools have reduced injury rates by up to 40%, primarily by deploying countermeasures before workers hit high-risk thresholds.

Actionable strategies:

-

Integrate AI tools like ReadiSupervise into daily pre-shift safety meetings.

-

Use predictive heat stress alerts to schedule hydration breaks during peak temperature windows.

-

Train supervisors to interpret AI-driven risk scores and apply tailored interventions (e.g., rotation or reassignment).

Improved Operational Efficiency

Operational efficiency gains from AI stem from better visibility into individual and team readiness, task planning, and equipment health. AI-powered shift optimization uses predictive analytics to align workforce deployment with natural alertness curves and environmental risk factors. For example, logistics companies can reroute drivers or delay high-risk deliveries based on fatigue risk scores.

In oil & gas, integrating AI into field operations allows companies to manage shifts, assign safety-critical tasks when workers are most alert, and minimize unproductive downtime. These efficiencies translate into faster cycle times, better resource allocation, and lower fatigue-related delays.

Actionable strategies:

-

Combine ReadiScore insights with scheduling tools to build “fatigue-aware” rosters.

-

Use historical fatigue and task performance data to create shift templates optimized for cognitive performance.

-

Apply AI-generated heat maps to dynamically assign teams based on site-level risk profiles.

Data-Driven Decision Making

Traditional safety programs often rely on static reports, anecdotal feedback, or lagging indicators like incident rates. AI brings dynamic, high-resolution data into the decision-making process. Dashboards provided by platforms like Readi deliver real-time fatigue risk distribution, enabling supervisors to log and justify stand-downs, reassignments, or wellness interventions with full transparency.

At an organizational level, AI-generated analytics help safety and HR leaders identify long-term patterns: which shifts, roles, or locations are most exposed to fatigue or mental health risks? With this insight, companies can invest in targeted prevention measures rather than broad, unfocused programs.

Actionable strategies:

-

Deploy cross-site dashboards to compare fatigue risk by geography or crew.

-

Use machine learning outputs to revise training protocols based on observed behavior trends.

-

Share AI-derived safety insights with leadership to align strategy with field conditions.

Reduced Costs

Workplace incidents come with steep direct and indirect costs: medical expenses, downtime, regulatory fines, and reputational damage. By proactively mitigating risk, AI reduces these burdens significantly. Predictive maintenance avoids catastrophic equipment failures. Fatigue prediction minimizes vehicle collisions, which are among the costliest incident types.

Additionally, AI enables smarter staffing, reducing overtime costs and unnecessary scheduling fluctuations. In logistics and utilities, where turnover and absenteeism impact continuity, predictive health insights also help reduce churn by identifying workers at risk of burnout.

Actionable strategies:

-

Run cost-benefit analyses comparing fatigue incident rates before and after AI deployment.

-

Quantify savings from predictive maintenance alerts tied to sensor data.

-

Track ROI by correlating AI interventions with reductions in lost-time incidents.

Better Compliance

AI tools streamline the compliance process by automating documentation, tracking metrics, and flagging anomalies. Systems like Readi automatically log fatigue scores, task adjustments, and supervisory actions—simplifying audits for OSHA, MSHA, and internal policies.

AI also helps organizations demonstrate a culture of care and diligence, which is increasingly valued in unionized and regulated environments. Tools that protect privacy while enhancing safety—like Readi’s anonymized scoring—align with modern expectations for ethical data use.

Actionable strategies:

-

Incorporate AI-driven safety logs into quarterly compliance reporting.

-

Use fatigue and exposure heatmaps as supporting material during regulatory reviews.

-

Build internal dashboards showing compliance trends over time for safety committees.

What Challenges Must You Address When Implementing AI?

Data Privacy and Ethics

AI tools are inherently data-intensive, which can trigger privacy concerns among workers. Continuous monitoring of sleep, location, or biometric data may feel invasive if not handled transparently. Readi mitigates this by sharing only aggregate and anonymized ReadiScores with supervisors—no personal or raw sleep data is exposed.

Ethical implementation also means being clear about how AI decisions are made and ensuring algorithms do not embed bias. For example, a system that penalizes night shift workers more harshly than day crews may unintentionally reinforce inequities.

Actionable strategies:

-

Conduct worker consultations during implementation to co-create privacy policies.

-

Publish clear documentation on how AI scores are calculated and used.

-

Establish governance protocols for periodic audit of AI system outputs.

Technical and Integration Challenges

Integrating AI into legacy safety systems often requires technical adjustments. Some companies face hurdles like outdated EHS platforms, poor data quality, or limited connectivity at remote sites. Tools like Readi are designed to be lightweight, integrating with ELDs, workforce management tools, and camera systems through APIs.

But AI predictions are only as good as the data inputs. Inaccurate shift logs, incomplete sleep data, or inconsistent sensor readings will degrade performance. Organizations must invest in data hygiene and IT support to fully capitalize on AI’s potential.

Actionable strategies:

-

Begin with a limited-scope pilot to test integrations and data pipelines.

-

Designate internal AI champions from IT and operations to troubleshoot issues.

-

Build a tech stack roadmap for scaling AI systems across departments.

Organizational Readiness

Even the best AI system will fail without workforce buy-in. Frontline workers may view AI as intrusive or as a threat to autonomy. Supervisors may be reluctant to trust AI predictions over personal experience. Leadership might hesitate to fund unproven technology.

Overcoming this requires strong change management. Begin with education: show workers how AI supports—not replaces—their expertise. Highlight success stories where AI prevented incidents. Use pilot programs to demonstrate real ROI and gather feedback.

Actionable strategies:

-

-

Appoint internal champions (e.g., safety supervisors) to lead change adoption.

-

Offer training sessions that demystify AI concepts using relatable examples.

-

Celebrate small wins publicly to reinforce momentum and credibility.

-

FAQ: Common Questions About AI and Occupational Health

What is the role of AI in occupational health?

AI helps predict and prevent workplace health risks using real-time data and machine learning. It transforms occupational health from reactive to proactive.

How can AI improve workplace safety?

AI enables early warnings, personalized risk insights, and real-time alerts. It empowers supervisors to take preventive action.

What are the benefits of using AI in occupational health and safety?

-

Fewer incidents and injuries

-

Higher productivity

-

Data-driven decisions

-

Better compliance and reporting

What are the challenges of implementing AI in occupational health?

-

Data privacy concerns

-

Integration with legacy systems

-

Change management and workforce trust

What job opportunities exist in AI and occupational health?

-

Data analysts and safety data scientists

-

AI system integrators and engineers

-

Occupational health specialists with AI skills

-

Training professionals for AI-powered safety tools

Related Posts

-

Can You Predict Fatigue Risk in Mining Without Wearables? New Research on Survey-Based Deep Learning Techniques for Measuring Fatigue Says YesFatigue is one of the biggest safety and performance risks in mining operations and other heavy industries. Workers who are tired...

-

An Interview with International Mining Magazine: A New Approach to Fatigue Management in MiningMining safety has always relied on layers of protection. What’s changing now is where those layers start.

-

Shifting From Reactive Dash Cam Safety to a Proactive Safety StrategyDash cams are now common across trucking fleets, mine sites, and people-transport operations. They help reconstruct incidents,...