If you're a health and safety manager working in a safety-critical industry such as mining, transportation, or heavy equipment, then you’re likely already well aware of the consequences of fatigue on the job. Long hours, shift work, and demanding schedules all increase the risk of fatigue-related incidents. And while you may already have processes in place to manage these risks, identifying the right fatigue management software to prevent incidents before they happen can be an overwhelming task.

Download the EHS Buyer's Guide to Readi and discover everything you need to know about our fatigue management software, pilot process, and implementation.

We'll help you understand exactly what to look for when choosing fatigue management software. We’ll also walk you through what Readi, a predictive fatigue management software solution from Fatigue Science, offers—and what’s required for a successful implementation.

Whether you're just starting your evaluation or are preparing for a rollout, you’ll find practical, actionable insights to guide your next steps.

Why Fatigue Management Software Matters

Fatigue is one of the most persistent and underreported risks facing safety-critical industries today. According to industry data, fatigue contributes to over 20% of serious transportation incidents. In other industrial contexts, fatigue has been shown to nearly double the risk of workplace injuries. This isn’t just a health concern; it’s a threat to productivity, safety, and operational efficiency.

A modern fatigue management software platform like Readi gives you the tools to:

-

Accurately forecast when and where fatigue will present the highest risk.

-

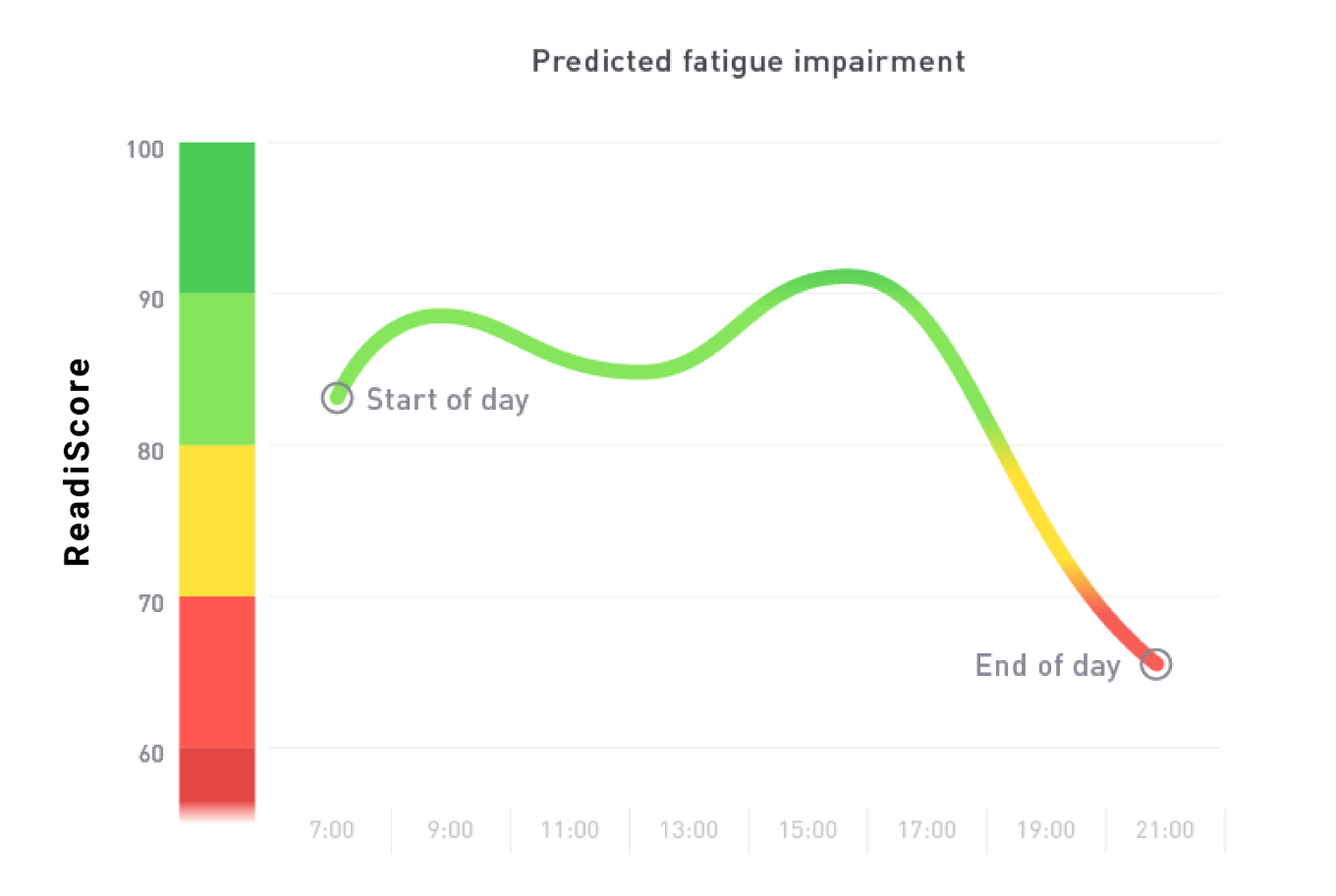

Quantify fatigue risk at the individual, crew, and site-wide level.

-

Equip supervisors with real-time dashboards, ReadiScores, and actionable recommendations.

-

Ensure fatigue countermeasures are documented and tied into safety compliance processes.

With Readi, you're not reacting to fatigue incidents after the fact. You’re proactively managing risk before safety or productivity is compromised.

Meet Readi: Predictive Fatigue Management Software Built for Safety-Sensitive Industries

Readi is a predictive fatigue management software platform built for the realities of industrial operations. More than 100 organizations worldwide rely on Readi to reduce incidents, support decision-making, and improve shift planning. It’s built on the SAFTE™ biomathematical model—used by the US Army and Federal Aviation Administration—and enhanced by over 15 years of operational data and advanced machine learning.

Why Readi Stands Out

| Feature | Readi Fatigue Management Software | Traditional Camera-Based Systems |

|---|---|---|

| Predicts fatigue | ✅ | ❌ |

| Real-time supervisor alerts | ✅ | ✅ |

| Personalized risk forecasts | ✅ | ❌ |

| Wearable or no-wearable options | ✅ | ❌ |

| Fatigue-informed shift scheduling | ✅ | ❌ |

Not all fatigue tools are built the same. Readi helps you get ahead—not just respond after an incident.

Readi is purpose-built for safety-critical environments. Here’s what makes it different:

-

It provides personalized, hour-by-hour fatigue forecasts for each worker, derived from high-accuracy sleep tracking or machine learning estimates.

-

It supports multiple deployment configurations, including wearable-only, ML-only, and hybrid setups to match your organization’s infrastructure.

-

It integrates seamlessly with your existing systems, such as Time & Attendance platforms (e.g., SAP, Kronos), Electronic Logging Devices (e.g., Geotab, Samsara), and Fleet Management Systems.

-

It delivers a clear return on investment: In one deployment, a mining operation saw a 50% reduction in fatigue-related alarms from their in-cab camera system after layering in Readi.

What’s Included in the Readi Platform:

-

ReadiWatch: Provides wearable-based sleep tracking with >92% validated accuracy.

-

ReadiML: Uses ELD data and historical sleep profiles to model fatigue risk without wearables.

-

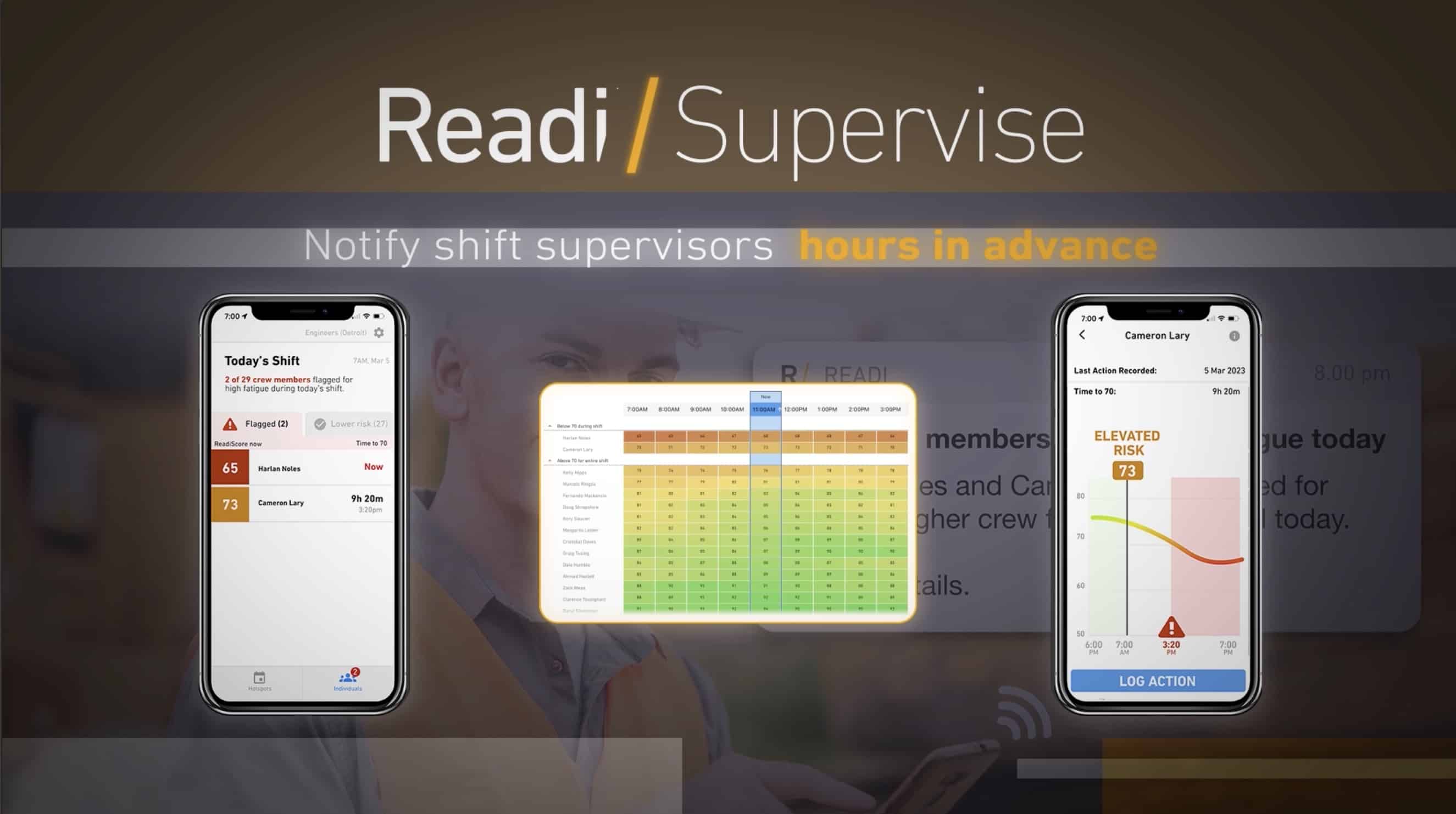

ReadiSupervise: Offers daily fatigue forecasts for each crew, enabling better task assignments and shift planning.

-

ReadiAnalytics: Delivers dashboards and trend analysis for safety, operations, and executive leadership.

-

Instant Insights: A schedule simulation tool that lets you redesign shifts to reduce future fatigue risk.

“We can now pinpoint fatigue hotspots and implement countermeasures tailored to the needs of our workers.” — Hector Miranda, GM, Orica

The Buying Committee: Who Needs to Be Involved?

Purchasing Readi isn’t a solo decision. It involves coordination across your organization. Here’s who you’ll need to align:

-

IT: Reviews system integration, data security, and infrastructure requirements.

-

Legal: Ensures SaaS terms, union compliance, and data privacy policies are met.

-

Finance: Evaluates the pricing model and total cost of ownership.

-

Health & Safety: Confirms that Readi aligns with safety KPIs and standard operating procedures.

-

Operations: Assesses impact on current shift planning and team workflows.

-

Supervisors: Needs assurance that Readi supports day-to-day responsibilities without disruption.

-

Executives: Looks for strategic alignment and scalability for future growth.

What a Readi Pilot Looks Like: Timeline, Scope, and Support

Fatigue Science recommends beginning with a pilot phase—typically 3 to 6 months—to validate impact before scaling. Here’s what to expect:

Scope:

-

100–150 operators

-

3–10 engaged supervisors

-

One pilot site with operations leadership support

Timeline Overview:

-

Weeks 1–2: Stakeholder alignment, baseline objectives, system configuration, pre-launch survey

-

Weeks 2–4: Ship ReadiWatch devices, onboard users, set up machine learning configuration

-

Weeks 4–6: Supervisors begin using ReadiSupervise and dashboards; weekly check-ins begin

-

Week 6: Midpoint review to assess KPIs and adoption; recalibrate as needed

-

Weeks 7–12: Ongoing engagement, supervisor coaching, monitor fatigue trends and countermeasure application

-

Week 12: Final review of outcomes, disruption analysis, and expansion planning

Fatigue Science Provides:

-

Supervisor enablement and training

-

Data integration support

-

Weekly check-ins and KPI tracking

-

Disruption analysis and success reporting

Defining Your Readi Pilot Success Metrics

Success is easier to achieve when it’s clearly defined. Consider setting metrics across these four categories:

Behavioral Metrics:

-

80%+ supervisor log-ins within 30 days

-

ReadiScore used in daily crew briefings

-

Documented countermeasures based on fatigue scores

Operational Metrics:

-

Reduction in fatigue camera alarms

-

Improved break scheduling and task planning

Change Management Metrics:

-

Supervisor endorsement and crew trust in the system

-

Increased safety awareness and adoption of dashboards

Technical Metrics:

-

Integration with existing systems validated

-

Minimal disruption reported by field teams

Final Readiness Checklist: Are You Ready for Readi?

Before you expand your Readi deployment, make sure these conditions are met:

-

Stakeholders across IT, safety, operations, legal, and finance are aligned.

-

You’ve selected a pilot site and assigned committed champions.

-

Internal KPIs and success metrics are clearly documented.

-

You’re prepared to participate in weekly review meetings with Fatigue Science.

-

Communication plans and reporting cadences are ready to go.

Get a Demo

Readi is more than just a fatigue management dashboard. It’s a predictive, proactive software platform that brings science, data, and real-world usability together to help teams make safer decisions every day.

If you're ready to stop guessing and start predicting, we invite you to take the next step.

Book a 15-minute walkthrough to see how Readi works.

Related Posts

-

What Is a ReadiScore and How Does It Work?What You’ll Learn What ReadiScore is and how it quantifies fatigue risk How it works with or without the ReadiWatch using AI and...

-

How an Underground Mine in Mexico Is Using Readi to Mitigate Fatigue RisksSummary Underground Mining Operation, Mexico Commodities: Gold and silver 153 ReadiWatch users 12-hour rotating shifts from 7...

-

How a South American Mining Operation Uses Readi to Manage Fatigue Risks in Their People Transport, MineOps, and Dangerous Materials UnitSummary Mining Company, South America 350+ operators using ReadiWatches, including both employees and contractors 7-day rotating...

.jpg)