Summary

- Remote transportation company

- 24/7 operations

- 4D-4N-4O roster schedule 12-hour shifts

- Drivers sleep at camp

Background

A transportation company operating in remote locations implemented the Readi fatigue risk management system (FRMS) to enhance the safety of its 24/7 operations. Using a system that monitors drivers' individual fatigue levels, the company improved risk management and eliminated fatigue-related incidents among monitored drivers.

The Need for Real-Time Fatigue Insights

Fatigue is an inherent risk in the transportation industry, especially in demanding and remote environments. Before implementing a comprehensive fatigue management solution, the transportation company relied on pre-start self-assessments and supervisory assessments to gauge fitness for work. These traditional approaches offered limited insights into real-time fatigue levels and were unable to prevent incidents.

As a result, the company sought a more reliable, data-driven solution to manage driver fatigue and improve overall safety.

Implementing Readi

The company conducted a 3-month Readi pilot program that provided predictive fatigue scores based on real-time sleep data. Following the pilot’s success, the platform was rolled out to a large population of high-risk drivers. By syncing sleep data to supervisors’ devices, supervisors used ReadiSupervise to monitor drivers’ fatigue levels up to 18 hours in advance and take action to mitigate risks.

With real-time data on driver fatigue, supervisors can now implement a range of fatigue mitigation strategies, such as:

- Assigning rest breaks based on fatigue levels.

- Rotating tasks to reduce cognitive fatigue.

- Holding regular fatigue awareness sessions to educate drivers on managing their sleep health.

- Adjusting shift schedules to better align with natural fatigue patterns.

Key Features of Readi

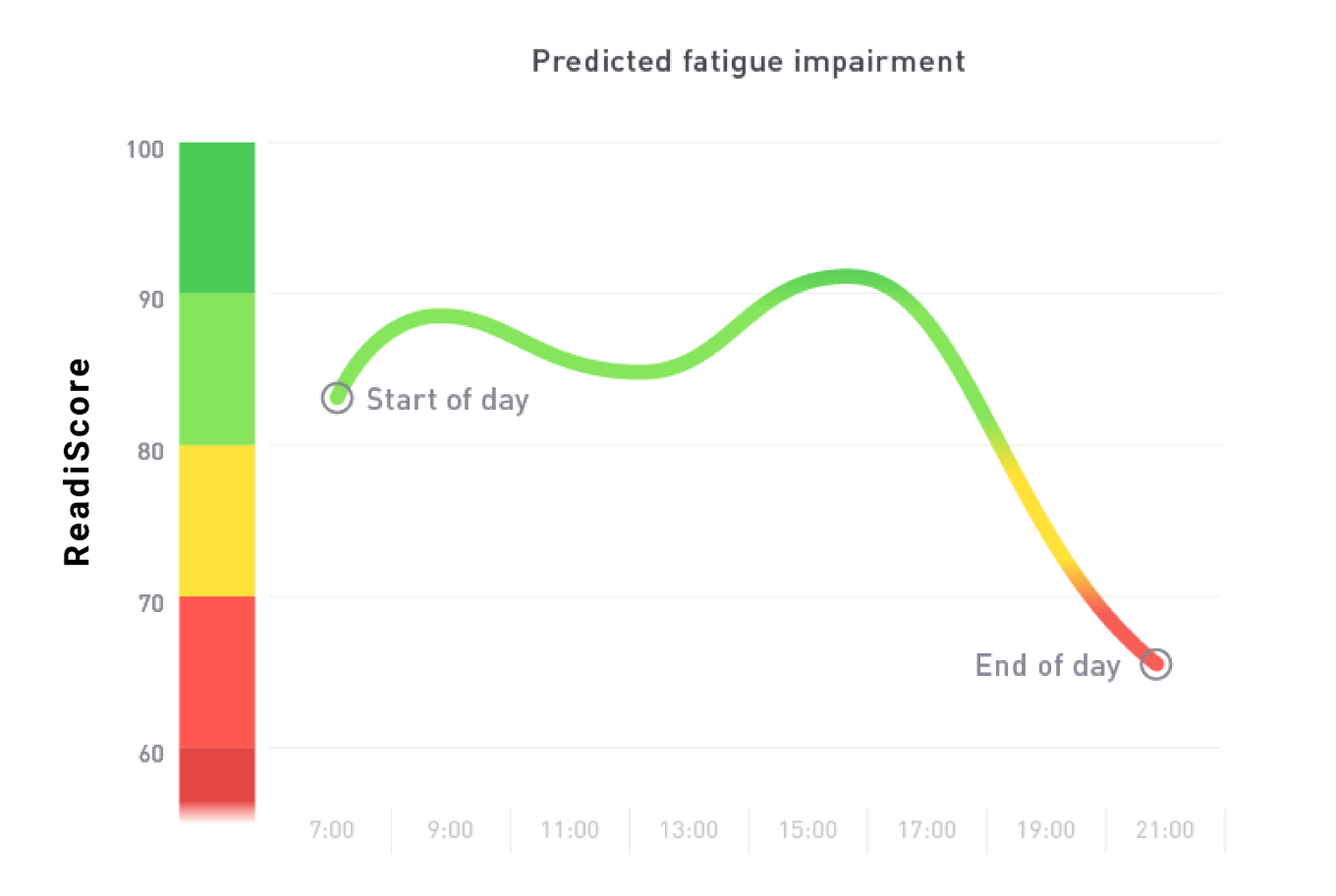

- Predictive Fatigue Scores: Drivers receive personalized fatigue scores, which supervisors use to make decisions about task assignments and rest breaks.

- Data-Driven Decision Making: Fatigue hotspots are identified by analyzing operational data, allowing the company to take proactive risk mitigation measures.

- Actionable Insights: The system flags when a driver is too fatigued to continue working safely, enabling task rotation and stand-downs as needed.

Results: Zero Fatigue-Related Incidents

Since implementing Readi, the company has seen a significant reduction in fatigue-related incidents. Among the monitored drivers, no fatigue-related incidents were reported. This demonstrates the effectiveness of the system in both preventing incidents and improving operational safety.

Future Expansion Plans

Given the success of the system, the company plans to extend its use to more drivers in its fleet. This expansion will provide greater protection and visibility into fatigue levels, further reducing the risk of fatigue-related incidents.

Related Posts

-

Top AI Trends for Fleets in 2026The trucking industry is entering a new phase of digital maturity. What began as basic telematics and compliance automation is...

-

Fleet Insurance Bleeding Your Margins? Here’s How to Fight Back with Proactive Risk ManagementFor fleet operators, insurance is a volatile, growing burden that can make or break margins.

-

Fatigue, Fleet Safety, and the Nuclear Verdict Era: Why Predictive Risk Management Is No Longer OptionalThe trucking industry is under legal siege. As reported by the American Transportation Research Institute (ATRI), litigation...