What’s behind the Readiband? How we measure and predict fatigue

The Readiband

When we talk about our technology, you’ll hear us say that Readiband can measure both sleep and fatigue.

The sleep analysis is usually easier to understand – Quite simply, Readiband provides really accurate insight into how your team sleeps. Things like how well they sleep after games, how long they sleep on average, and what time they fall asleep when traveling to a different time zone.

The fatigue analysis is where Fatigue Science really makes its name. Measuring fatigue is not as simple as asking someone how tired they feel today, and predicting fatigue is not as simple as asking someone how tired they’ll be two weeks from now. Scientists identify fatigue by measuring an individual’s sustained attention and reaction time. To do this, they use a psychomotor vigilance task (or PVT) test. A PVT is a small electronic box with buttons and lights – When a light flashes, the individual must push a button, the faster they push the button, the faster their reaction time measurement and the higher the PVT score. Sounds simple enough, but PVT tests are impractical to use in the real world, and can only provide a fatigue measurement for the exact moment in time that the test is taken. The Readiband, however, provides a continuous measurement of fatigue based on the sleep data it collects and something called the SAFTE (Sleep, Activity, Fatigue, Task and Effectiveness) model, which predicts the wearer’s PVT score.

What is SAFTE?

The Walter Reed Army Institute of Research at the U.S. Army Medical Research Development Command started to invest in research to understand how long periods of wakefulness during critical operations were affecting their soldiers ability to react quickly and make effective, split-second decisions. From this research, a biomathematical model called SAFTE was developed. The SAFTE model is an algorithm, which processes information about sleep history and time of day, to predict PVT test scores. The model was built into a software used in schedule planning, to both understand and limit the dangerous effects of fatigue in military operations.

The Walter Reed Army Institute of Research at the U.S. Army Medical Research Development Command started to invest in research to understand how long periods of wakefulness during critical operations were affecting their soldiers ability to react quickly and make effective, split-second decisions. From this research, a biomathematical model called SAFTE was developed. The SAFTE model is an algorithm, which processes information about sleep history and time of day, to predict PVT test scores. The model was built into a software used in schedule planning, to both understand and limit the dangerous effects of fatigue in military operations.

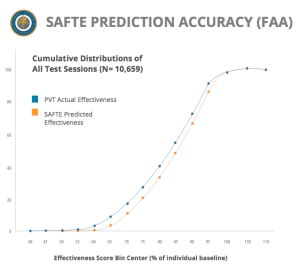

The ability of the SAFTE model to accurately predict PVT scores and therefore, predict performance and fatigue, was proven through a number of studies including those conducted by the US Department of Transportation’s Federal Railroad Administration and the Federal Aviation Administration. This means the SAFTE model is scientifically proven to provide accurate measurements and predictions of reaction time for your athletes without the need to coordinate PVT or other timed tests.

The SAFTE model is licensed exclusively by Fatigue Science for use in the Readiband. By using Readiband to monitor your athletes’ sleep quality, you can harness the power of military fatigue research and development to understand how that sleep affects their athletic performance and reaction time.

For deeper reading, please refer to the following papers:

Comparison of Mathematical Model Predictions to Experimental Data of Fatigue and Performance

Journal of Aviation, Space and Environmental Medicine (2004)

Fatigue Models for Applied Research in Warfighting

Journal of Aviation, Space and Environmental Medicine (2004)