Ensuring the safety and well-being of workers is paramount. Heavy industries, such as mining, construction, and transportation, face unique challenges when it comes to mitigating risks and preventing accidents.

Traditional safety measures often rely on reactive approaches, addressing issues after incidents occur. However, the emergence of predictive safety analytics is revolutionizing the way heavy industries approach workplace safety.

By harnessing the power of data and advanced analytics, organizations can now proactively identify potential hazards and take preventive measures before accidents happen. Predictive safety analytics empowers companies to create safer work environments, reduce incidents, and prioritize the well-being of their employees.

What are Predictive Safety Analytics?

Predictive safety analytics is an innovative approach that leverages data analysis and machine learning techniques to anticipate and mitigate safety risks in heavy industries. This proactive method goes beyond traditional safety measures by using historical data, real-time inputs, and predictive modeling to forecast potential hazards and prevent accidents before they occur.

The core components of predictive safety analytics include:

- Data Collection: Gathering relevant safety-related data from various sources, such as incident reports, equipment logs, sensor readings, and employee feedback.

- Data Processing and Analysis: Cleaning, organizing, and analyzing the collected data to uncover patterns, correlations, and trends that may indicate potential safety risks.

- Predictive Modeling: Developing sophisticated algorithms and models that can predict future safety incidents based on historical data and real-time inputs.

- Real-Time Monitoring and Alerts: Continuously monitoring safety conditions and generating alerts when the system detects a high likelihood of an incident occurring.

By employing these components, predictive safety analytics enables organizations to identify and address safety risks proactively. This data-driven approach helps prioritize safety initiatives, optimize resource allocation, and foster a culture of prevention rather than reaction.

The benefits of implementing predictive safety analytics in heavy industries are significant—reduced accidents and injuries, improved operational efficiency, lower costs associated with incidents, and enhanced employee morale and productivity. Companies that embrace this technology can gain a competitive edge by demonstrating their commitment to worker safety and well-being.

How Can Predictive Safety Analytics Improve Safety in Heavy Industry?

Predictive analytics revolutionizes safety protocols in heavy industry by providing a forward-looking approach to risk management. This innovative method enhances the understanding of potential hazards, allowing for preemptive actions that protect both personnel and assets. With an emphasis on data interpretation, companies can anticipate and mitigate issues before they escalate.

Enhanced Risk Identification

- Advanced Insight Generation: By leveraging machine learning, predictive analytics uncovers intricate relationships within operational data. This capability allows for the identification of subtle indicators of risk, such as equipment performance shifts that could signal upcoming maintenance needs.

- Continuous Operational Oversight: Implementing systems that monitor conditions around the clock ensures that any deviation from safe operating parameters is promptly addressed. This vigilance enables timely interventions, maintaining safety and operational continuity.

- Predictive Risk Assessment: Through the application of statistical models, organizations can project the likelihood of safety incidents. This foresight is critical in high-hazard environments, providing a dynamic understanding of risk factors and allowing for agile responses.

Proactive Safety Management

- Targeted Resource Allocation: By pinpointing areas of greatest concern, predictive analytics directs resources efficiently to where they are needed most. This strategic deployment reduces unnecessary costs and enhances the efficacy of safety measures.

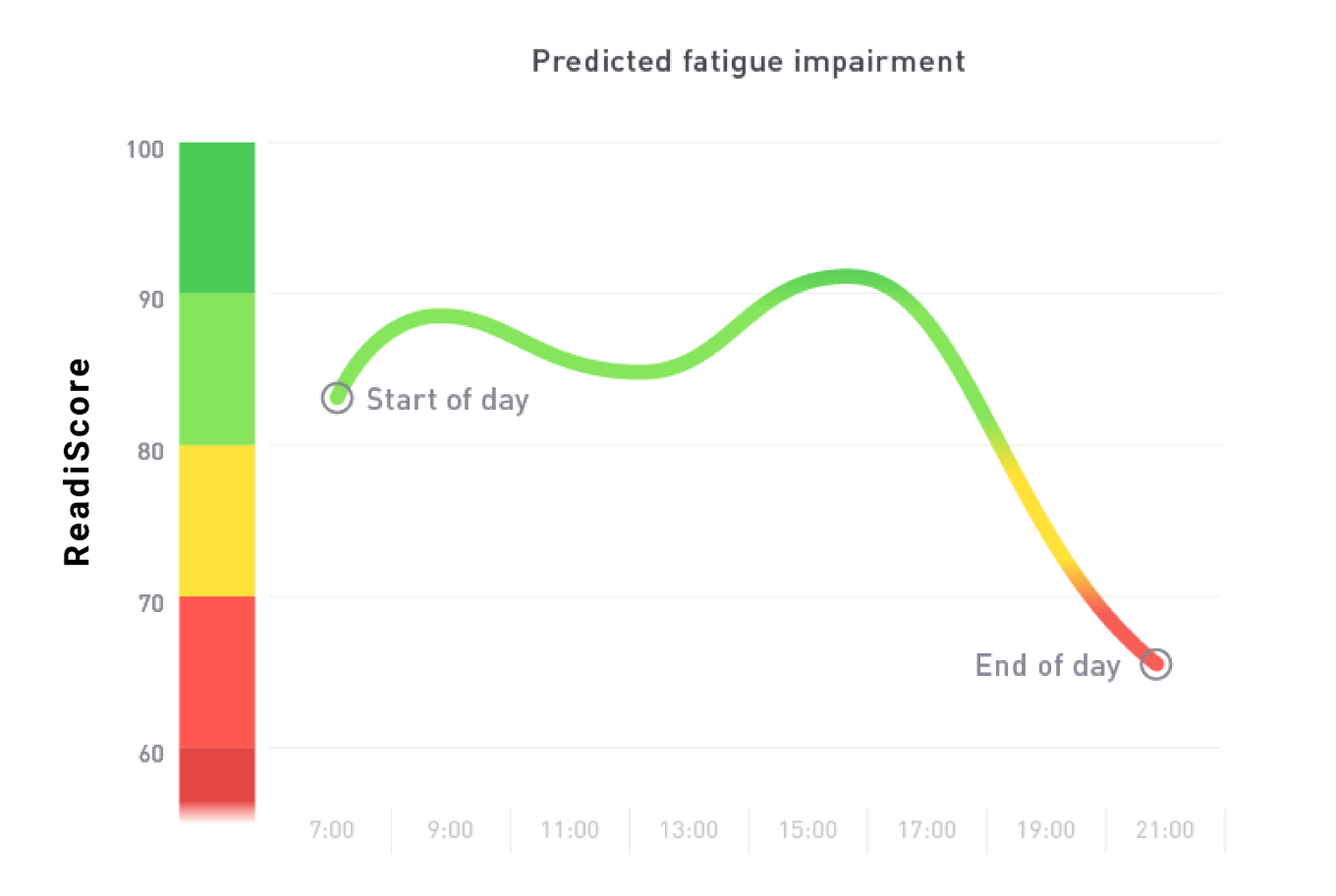

- Comprehensive Fatigue Solutions: Addressing worker fatigue through data analysis enables the adjustment of schedules and processes to minimize risk. By incorporating insights into work patterns and environmental factors, companies can enhance overall safety and productivity.

- Empirical Decision Support: The detailed insights offered by predictive analytics equip safety managers with the evidence needed to make informed decisions. This data-driven approach ensures strategies are effective and aligned with organizational safety goals.

By integrating predictive analytics, heavy industries can foster a culture of proactive safety management, continuously adapting to new risks and maintaining high safety standards. This approach not only enhances immediate safety outcomes but also supports long-term operational resilience.

Predictive Safety Analytics vs Current Practice for Health and Safety in Heavy Industry

The existing safety protocols within heavy industries predominantly focus on addressing issues post-incident. This approach is reactive, relying heavily on incident reports and compliance checks to inform procedural adjustments. In contrast, predictive safety analytics introduces a forward-thinking strategy that anticipates potential risks, allowing for intervention before incidents occur.

Comparative Analysis

- Data Utilization: Traditional safety systems often limit themselves to historical data that provides a partial view of safety dynamics. Predictive analytics, however, leverages comprehensive data sets from diverse sources, offering a holistic perspective that equips organizations to anticipate and mitigate risks efficiently.

- Incident Response vs. Anticipatory Measures: Established practices center on retrospective analysis and corrective actions after an incident. Predictive safety analytics, on the other hand, employs advanced analytical tools to forecast risks, enabling organizations to implement anticipatory measures that prevent incidents and enhance safety performance.

- Optimized Resource Deployment: Current methodologies allocate resources based on static historical data, which may not address evolving risks effectively. Predictive analytics allows for dynamic resource deployment, directing attention and investment to emerging risk areas, ensuring that safety efforts are both timely and impactful.

Integration and Adaptability

- System Cohesion: Traditional safety systems often operate in silos, lacking integration with broader organizational processes, which can hinder comprehensive safety management. Predictive safety analytics solutions are designed to integrate seamlessly with existing systems, enhancing data synergy and improving overall safety outcomes.

- Scalability and Flexibility: As industrial environments evolve, so do their safety challenges. Predictive analytics platforms are inherently scalable and flexible, continuously adapting to new data and operational contexts. This ensures that safety strategies remain effective and aligned with current conditions, supporting long-term safety objectives.

By adopting predictive safety analytics, heavy industries can transition from a reactive to a proactive safety framework, thereby improving safety outcomes, enhancing efficiency, and fostering a culture of continuous improvement.

How to Implement Predictive Safety Analytics in Heavy Industry

Embarking on the journey to implement predictive safety analytics involves a strategic integration of technology, processes, and personnel. This approach not only enhances safety but also streamlines operations by embedding predictive insights into the core of safety management practices. A methodical implementation ensures that the transition is smooth and that the full potential of predictive analytics is realized.

Assess Current Safety Protocols

Initiating the implementation of predictive safety analytics requires a foundational understanding of your existing safety systems. Begin by conducting a comprehensive review to identify inefficiencies and potential enhancements. This analysis not only uncovers immediate weaknesses but also provides a roadmap for integrating advanced analytics tailored to your operational dynamics.

Detailed Safety Assessment Steps

- Comprehensive Documentation Audit: Conduct a thorough audit of safety documentation, including compliance records and incident logs, to discern recurring patterns and underlying issues.

- Field Observations: Perform in-depth field observations to assess the real-world application of safety measures. Focus on high-risk zones, scrutinizing machinery operations and worker interactions to identify latent hazards.

- Collaborative Discussions: Facilitate open discussions with employees across all levels, from operational staff to senior management, to capture a wide array of insights and unreported safety concerns.

Aligning Analytics with Industry-Specific Challenges

Recognizing the distinct safety landscapes of industries like mining, transportation, construction, utilities, and oil & gas is crucial. Each field presents its own set of challenges, such as the intricate logistics in transportation or the hazardous material handling in mining. Understanding these specificities guides the customization of predictive analytics to effectively preempt sector-specific risks.

- Mining: Leverage data on geological surveys and equipment diagnostics to predict and mitigate the risks associated with subterranean operations and machinery use. Leverage AI-driven fatigue risk management software like Readi to predict and mitigate operator fatigue.

- Transportation: Focus on analyzing driver behavior patterns, vehicle telematics, and environmental data to anticipate and prevent accidents, ensuring safe navigation.

- Construction: Use information on materials management, site logistics, and worker compliance to foresee potential accidents or structural failures, enhancing safety protocols.

- Utilities and Oil & Gas: Emphasize monitoring of equipment performance, environmental conditions, and worker health metrics to predict system failures or exposure hazards, thereby protecting both personnel and infrastructure.

By conducting a meticulous assessment and understanding the unique attributes of your sector, predictive safety analytics can be seamlessly integrated to fortify your existing safety framework, promoting a proactive stance in risk management.

Collect Relevant Data

The strength of predictive safety analytics relies heavily on the diversity and depth of the collected data. To build effective predictive models, it's crucial to gather a wide range of data points, each contributing unique insights into operational safety. By systematically compiling information from varied sources, organizations can construct a comprehensive safety profile that supports proactive risk management.

Wide-Ranging Data Sources

- Safety Records: Review historical safety records to uncover persistent issues and trends. This archival data serves as a foundation for understanding factors that contribute to past incidents.

- Operational Metrics: Analyze operational metrics and machinery usage data to identify patterns that may indicate impending equipment failures. Regular tracking of these metrics helps in forecasting maintenance needs and reducing unexpected downtimes.

- Worker Observations: Solicit input from employees to capture on-the-ground observations and unofficial accounts of near-misses. Frontline workers can provide critical insights into potential hazards that are not captured in formal reports.

Industry-Specific Data Collection Strategies

In sectors like mining, the data collection strategy should encompass specific variables that directly impact safety. For instance, understanding the operational environment through detailed geological assessments and monitoring site conditions is vital. Capturing data on subterranean stability, atmospheric conditions, and equipment operation provides a nuanced view that enhances the accuracy of predictive analytics.

- Geological Assessments: Conduct and record detailed geological assessments to predict and mitigate risks associated with underground operations and terrain stability.

- Atmospheric Monitoring: Implement systems to continuously monitor atmospheric conditions, including gas levels and temperature, to ensure a safe working environment.

- Usage and Maintenance Logs: Maintain comprehensive logs of equipment usage and maintenance to predict wear and tear, facilitating timely interventions to prevent machinery-related incidents.

By assembling a multifaceted dataset tailored to sector-specific needs, predictive safety analytics can be effectively leveraged to fortify safety protocols. This approach not only enhances predictive capabilities but also fosters a culture of safety that prioritizes proactive risk identification and mitigation.

Use Advanced Analytical Tools

Integrating advanced analytical tools into safety management practices marks a pivotal shift toward a more proactive safety culture in heavy industries. These tools are adept at navigating and analyzing complex datasets, uncovering hidden trends and forecasting potential safety risks with precision. Their implementation transforms data into strategic insights, supporting informed decisions and preventive safety initiatives.

Harnessing Predictive Technologies

- Efficient Data Handling: Cutting-edge tools are designed to efficiently handle substantial volumes of data, ensuring swift and accurate extraction of insights. This capability is essential in environments where data is perpetually generated from myriad sources, such as sensors and machinery logs.

- Complex Trend Analysis: By leveraging robust algorithms, these technologies unearth intricate trends and relationships within the data. Identifying these trends allows organizations to anticipate potential safety risks and implement preemptive actions.

- Dynamic Risk Forecasting: Tools equipped with dynamic forecasting capabilities provide continuous evaluations of impending risks. By consistently analyzing real-time data, they enable ongoing risk assessments crucial for maintaining a safe and adaptive industrial environment.

Diverse Predictive Solutions

A variety of predictive solutions are tailored to the unique needs of heavy industries, each equipped with distinct features to tackle specific safety challenges.

- Fatigue Prediction Systems: Systems such as those offered by Fatigue Science utilize predictive analytics and machine learning to identify and mitigate fatigue-related hazards. By evaluating factors like sleep patterns and work schedules, they help avert incidents stemming from worker fatigue.

- Environmental Risk Monitors: In industries susceptible to extreme environmental conditions, these monitors track factors like temperature and humidity. They predict risks associated with heat stress and provide recommendations for protective measures.

- Equipment Safety Analytics: Tools focused on equipment safety analyze usage data, maintenance schedules, and operational conditions. By predicting potential failures, they facilitate timely maintenance and reduce the likelihood of equipment-related incidents.

Empowering Safety Through Insights

Employing these advanced analytical tools provides a detailed understanding of safety concerns, enabling organizations to implement strategic, proactive measures suited to their specific operational needs. The insights gained from predictive technologies empower safety leaders to not only address current challenges but also anticipate future ones, fostering an environment of ongoing enhancement and preparedness. Through the integration of these tools, heavy industries can achieve superior safety outcomes and uphold the well-being of their workforce.

Integrate with Existing Safety Systems

Integrating predictive safety analytics within current safety frameworks is essential for maximizing their effectiveness. This process involves ensuring that predictive tools not only fit within existing structures but also enhance their functionality. By embedding these advanced analytics into your current protocols, organizations can achieve a more dynamic and responsive safety environment.

System Cohesion and Alignment

- Evaluate System Synergy: Begin by assessing how predictive analytics can synergistically interact with your existing safety systems. Focus on creating a seamless connection that allows for the effortless exchange and processing of data across platforms.

- Unified Safety Strategy: Ensure that predictive analytics aligns with your safety goals, enhancing traditional systems like emergency response and compliance monitoring. This alignment fosters a unified approach that leverages both historical data and real-time insights.

- Technological Integration: Align new analytical technologies with your operational objectives. This alignment ensures that predictive solutions not only integrate smoothly but also drive innovation and efficiency in safety management practices.

Elevating Safety Monitoring

- Streamlined Data Integration: Facilitating smooth data integration across safety platforms enhances the ability to monitor safety metrics in real-time. This integration enables safety managers to access actionable insights quickly, leading to prompt and informed decision-making.

- Enhanced Insight Visibility: By merging predictive analytics with existing systems, organizations gain greater transparency into safety operations. This visibility allows for continuous risk assessment and proactive adjustments to safety measures.

- Collaborative Safety Culture: A well-integrated system fosters a culture where predictive insights are shared across departments, promoting collaboration. This culture of shared responsibility and awareness enhances overall safety and encourages collective vigilance against potential hazards.

By effectively weaving predictive analytics into existing systems, organizations can build a robust safety management infrastructure. This integration not only enriches the predictive capabilities but also strengthens the entire safety framework, leading to improved safety outcomes and fortified operational resilience.

Train Your Team

Training your team effectively in predictive safety analytics is essential for embedding these technologies into your organizational framework. This process involves creating a robust educational plan that caters to various roles, ensuring all members—from management to operational staff—are well-versed in leveraging analytics to enhance safety measures. By cultivating a knowledgeable workforce, you promote a culture where safety is a shared commitment, driven by data-enhanced insights.

Tailored Educational Programs

- Role-Specific Training Paths: Design training programs that address the specific needs of different roles within your organization. Managers should focus on strategic data interpretation, while operational staff benefit from practical demonstrations on incorporating predictive tools into their routines.

- Continuous Development Opportunities: Establish a culture of ongoing learning with regular updates and sessions on the latest advancements in predictive safety analytics. This approach ensures that your team remains at the forefront of safety technology and practices.

Building a Culture of Safety

- Knowledge-Driven Empowerment: Provide employees with the expertise to confidently use predictive safety analytics. This empowerment fosters a proactive attitude towards safety, encouraging team members to take initiative in identifying and mitigating risks.

- Promoting Collaborative Practices: Encourage an environment where insights from predictive analytics are shared and discussed openly. This collaborative approach enhances team problem-solving capabilities, ensuring safety strategies benefit from diverse input and are more robust.

Evaluating Training Impact

- Feedback Mechanisms and Evaluation: Implement systems for gathering feedback on training effectiveness, allowing for continuous improvement and alignment with organizational safety goals.

- Impact Assessment Metrics: Develop specific metrics to evaluate the success of training programs, such as improvements in safety compliance and reductions in incident rates. These metrics provide clear indicators of how training contributes to overall safety performance.

By prioritizing tailored training and fostering a culture of continuous learning and collaboration, organizations can ensure their workforce is not only skilled in using predictive safety analytics but also actively engaged in promoting a safer work environment.

Monitor and Adjust

To maintain the effectiveness of predictive safety analytics, a proactive approach to ongoing observation and refinement is essential. This ongoing process ensures that systems remain responsive to shifts in safety challenges and operational conditions. By establishing a framework of regular assessments, organizations can enhance the precision and applicability of their safety analytics.

Systematic Observation Techniques

- Real-Time Data Review: Implement consistent scrutiny of predictive model outcomes to identify emerging patterns and deviations. This attentiveness facilitates timely refinements to safety strategies, keeping them pertinent to the current environment.

- Evaluation of Predictive Accuracy: Develop specific criteria to assess the accuracy and effectiveness of predictive analytics, such as the correlation between predicted risks and actual incidents. These criteria serve as benchmarks for continuous improvement.

Responsive System Enhancements

- Continuous Data Refresh: Regularly update data inputs to capture the latest operational dynamics and safety conditions. This practice is vital for ensuring predictive models are informed by the most recent and relevant information.

- Algorithm Adjustment: Regularly review and modify algorithms to optimize model performance. Fine-tuning these models ensures they adapt to changes in operational scenarios and emerging safety threats.

Continuous Learning and Adaptation

- Knowledge Expansion Initiatives: Facilitate ongoing training to keep staff informed about new features and enhancements in the predictive analytics system. This continuous learning ensures that team members maximize the technology’s potential in their safety efforts.

- Feedback Integration: Actively seek and incorporate user feedback to identify areas for training improvement and additional support. This approach encourages a collaborative environment where employees contribute to the evolution of training programs and safety practices.

By implementing a strategy of vigilant monitoring and adaptive refinement, organizations can ensure predictive safety analytics remain integral to their safety management systems, supporting both immediate safety enhancements and long-term operational adaptability.

Common Mistakes to Avoid When Implementing Predictive Safety Analytics in Heavy Industry

Successfully introducing predictive safety analytics in heavy industry requires attention to detail and strategic planning. Missteps during implementation can detract from the potential benefits, making it crucial to navigate these challenges with care.

Ensuring Data Integrity

- Prioritize Accurate Data: The accuracy and completeness of data are foundational to effective predictive analytics. Establish rigorous data validation protocols to maintain the reliability and consistency of your datasets.

- Comprehensive Data Strategy: Avoid narrow data collection by developing a strategy that captures diverse operational and safety parameters. This comprehensive approach ensures robust and actionable insights.

Smooth System Integration

- Facilitating Interoperability: Overcome integration hurdles by prioritizing system interoperability. Conduct thorough compatibility assessments to facilitate seamless interaction between predictive tools and existing infrastructure.

- Addressing Legacy Constraints: Acknowledge and plan for the limitations of legacy systems. Develop a phased approach to integration that accommodates older technologies while incorporating new analytical capabilities.

Engaging and Educating Staff

- Invest in Comprehensive Training: Effective use of predictive tools requires well-designed training programs. Tailor educational initiatives to equip employees at all levels with the skills needed to leverage analytics effectively.

- Fostering Stakeholder Involvement: Secure the success of implementation by engaging stakeholders throughout the process. Early involvement ensures alignment and fosters a collaborative environment conducive to innovation.

Aligning with Strategic Goals

- Integrating with Business Objectives: Ensure that predictive analytics efforts are aligned with organizational goals. Directly linking analytics initiatives to strategic objectives enhances their impact and relevance.

- Balancing Short and Long-Term Goals: Strive for a balance between immediate gains and sustained improvements. A long-term perspective ensures that safety enhancements are both impactful and enduring.

Avoiding these pitfalls in implementing predictive safety analytics is key to unlocking its full potential, positioning heavy industries to achieve significant safety and efficiency gains.

The Future of Safety in Heavy Industry

The future of safety in heavy industry will be significantly shaped by the integration of advanced technologies such as artificial intelligence and predictive analytics. These tools will redefine safety strategies, offering enhanced capabilities for risk management. As innovations continue to develop, their role in safety systems will facilitate nuanced analyses that enable organizations to foresee and address potential hazards more effectively.

The Role of Artificial Intelligence

- Sophisticated Analytical Capabilities: AI technologies provide the ability to process and analyze vast datasets with remarkable precision. Within safety systems, AI can draw insights from diverse sources—such as sensor data and equipment diagnostics—to detect subtle risk indicators that may not be visible through conventional analysis.

- Continuous System Optimization: AI systems are designed to adapt and learn from new data, continuously refining their models to improve accuracy. This adaptive capability ensures safety mechanisms evolve alongside operational changes, maintaining their relevance and effectiveness.

- Intelligent Response Mechanisms: As AI becomes more integrated, it will support intelligent response strategies, enabling systems to autonomously recommend or initiate safety measures. This capability reduces reaction times, ensuring swift interventions to mitigate identified risks.

The Impact of Predictive Analytics

- Anticipatory Risk Strategies: Predictive analytics will enhance the transition from reactive to anticipatory safety management. By utilizing data-driven insights, organizations can proactively address potential risks, thereby reducing the likelihood of incidents and improving safety resilience.

- Dynamic Safety Frameworks: Leveraging predictive insights allows for the development of adaptable safety frameworks that reflect both historical data and real-time analytics. This dynamic approach ensures safety protocols remain aligned with current operational realities.

- Integration with Emerging Technologies: The future will see predictive analytics increasingly converging with emerging technologies such as IoT and advanced wearables. This integration will enable real-time safety monitoring and provide actionable feedback to employees, empowering them to make informed decisions to maintain a safe working environment.

Embracing these technological advancements will transform workplace safety, enabling organizations to achieve higher levels of operational safety and efficiency. The integration of AI and predictive analytics will lead to a proactive safety culture focused on continuous improvement and prevention.

Predictive Safety Analytics FAQ

1. What Exactly Are Predictive Safety Analytics?

Predictive safety analytics involves utilizing sophisticated data processing techniques to foresee and address safety hazards within industrial settings. By analyzing a combination of historical data and real-time inputs, these analytics offer insights into potential risks, allowing for strategic planning and risk mitigation. This approach empowers industries to be proactive, significantly enhancing safety and operational effectiveness.

2. How Do Predictive Safety Analytics Enhance Traditional Safety Measures?

Traditional safety measures typically respond to incidents after they occur, relying on historical data for improvements. Predictive safety analytics shifts this paradigm by allowing organizations to anticipate issues before they arise, thereby supplementing existing safety protocols with a forward-thinking strategy. This integration leads to a comprehensive safety approach that reduces incident frequency and severity.

3. What Types of Data Are Necessary for Effective Predictive Safety Analytics?

For predictive safety analytics to function effectively, a wide range of data must be collected. This includes past incident logs, equipment usage statistics, environmental data, and direct feedback from employees. These diverse data sources enable the creation of predictive models that are finely tuned to the intricacies of the industrial environment, improving their accuracy and reliability.

4. Can Predictive Safety Analytics Integrate with Existing Technology?

Absolutely, predictive safety analytics are crafted to work harmoniously with current safety management frameworks. This compatibility allows organizations to enhance their existing systems without extensive restructuring. By integrating predictive capabilities, industries can leverage data-driven insights while maintaining their established safety processes.

5. What Challenges Might Be Faced When Implementing Predictive Safety Analytics?

Implementing predictive safety analytics can pose certain challenges that require careful consideration. These challenges include ensuring the integrity and completeness of data, achieving seamless integration with existing systems, and fostering user engagement and understanding. Addressing these issues involves strategic planning and comprehensive training to fully harness the potential of predictive analytics in enhancing safety outcomes.

As the landscape of safety in heavy industries continues to evolve, embracing predictive analytics will be a defining factor in achieving superior safety outcomes.

By harnessing the power of data and advanced technologies, organizations can foster a proactive safety culture that prioritizes prevention and continuous improvement. If you're ready to revolutionize your approach to safety management, book a demo to explore how Fatigue Science's predictive fatigue management software can improve safety and productivity – we're here to support you on your journey towards a safer, more efficient future.

Related Posts

-

Shifting From Reactive Dash Cam Safety to a Proactive Safety StrategyDash cams are now common across trucking fleets, mine sites, and people-transport operations. They help reconstruct incidents,...

-

Top AI Trends for Fleets in 2026The trucking industry is entering a new phase of digital maturity. What began as basic telematics and compliance automation is...

-

Fatigue, Fleet Safety, and the Nuclear Verdict Era: Why Predictive Risk Management Is No Longer OptionalThe trucking industry is under legal siege. As reported by the American Transportation Research Institute (ATRI), litigation...