https://fatiguescience.com/wp-content/uploads/2023/04/Readi-ELD-thumb.jpg

964

1192

Fatigue Science

http://fatiguescience.com/wp-content/uploads/2021/03/FatigueScience_White-1.svg

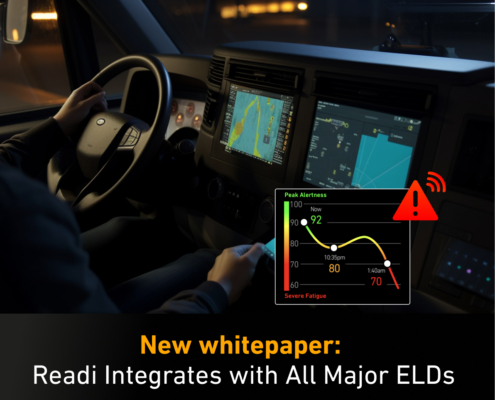

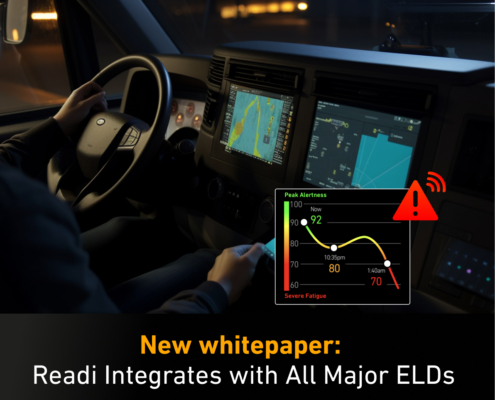

Fatigue Science2023-04-25 16:05:012023-04-25 16:05:01New Whitepaper: Readi Integrates with All Major ELDs to Predict Driver Fatigue

https://fatiguescience.com/wp-content/uploads/2023/04/Readi-ELD-thumb.jpg

964

1192

Fatigue Science

http://fatiguescience.com/wp-content/uploads/2021/03/FatigueScience_White-1.svg

Fatigue Science2023-04-25 16:05:012023-04-25 16:05:01New Whitepaper: Readi Integrates with All Major ELDs to Predict Driver Fatigue https://fatiguescience.com/wp-content/uploads/2023/04/Readi-ELD-thumb.jpg

964

1192

Fatigue Science

http://fatiguescience.com/wp-content/uploads/2021/03/FatigueScience_White-1.svg

Fatigue Science2023-04-25 16:05:012023-04-25 16:05:01New Whitepaper: Readi Integrates with All Major ELDs to Predict Driver Fatigue

https://fatiguescience.com/wp-content/uploads/2023/04/Readi-ELD-thumb.jpg

964

1192

Fatigue Science

http://fatiguescience.com/wp-content/uploads/2021/03/FatigueScience_White-1.svg

Fatigue Science2023-04-25 16:05:012023-04-25 16:05:01New Whitepaper: Readi Integrates with All Major ELDs to Predict Driver Fatigue