An Interview with International Mining Magazine: A New Approach to Fatigue Management in Mining

Mining safety has always relied on layers of protection. What’s changing now is where those layers start.

Across the industry, fatigue management in mining is moving upstream, away from relying only on alarms, near misses, and incidents, and toward earlier visibility into risk. This shift was recently explored in International Mining, where Fatigue Science shared how predictive fatigue insight is being used to help supervisors act before fatigue turns into an event.

Key Takeaways

-

Fatigue is increasingly treated as an operational risk, not a personal one

-

Mining leaders are moving from lagging indicators to leading indicators

-

Predictive fatigue insight helps supervisors act before a shift starts

-

Reactive tools like cameras still matter, but work best as a last line of defence

-

Non-wearable fatigue tools like Readi are gaining traction due to scale, privacy, and adoption

Fatigue Is No Longer Just a Personal Responsibility

For many years, fatigue management in mining depended heavily on self-reporting. Operators were expected to know when they were tired and speak up during the toolbox talk.

The challenge is that people are not particularly good at judging their own fatigue.

Fatigue Science explains that by the time someone feels tired, their performance, reaction time, and decision-making may already be affected. This is why fatigue is increasingly being treated like other site risks, something that can be anticipated and managed systematically rather than left to individual judgment.

The Limits of Reactive Fatigue Tools

In-cab camera systems and other reactive technologies have played an important role in improving mining safety, particularly in haulage and people transportation. They remain a critical control.

However, reactive tools have limitations.

They identify fatigue only once a worker is already at risk. They don’t prevent fatigued workers from entering high-risk tasks in the first place, and they can generate false alarms when used without broader context.

Fatigue Science explains that while reactive detection is necessary, it cannot prevent risk on its own.

Why Predictive Fatigue Management Is Gaining Ground

Predictive fatigue management uses sleep science, shift schedules, and circadian biology to estimate when fatigue risk is likely to increase—often hours before a shift begins.

Instead of reacting to alarms, supervisors gain early insight that allows them to:

-

Adjust task assignments

-

Apply controls to higher-risk shifts

-

Make fit-for-work and fit-for-task decisions earlier

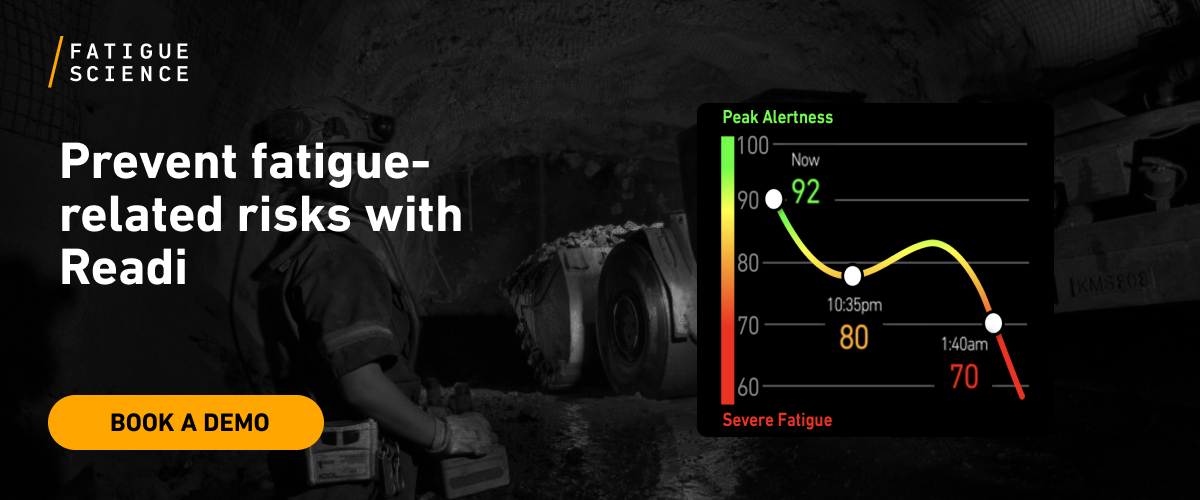

At Fatigue Science, this capability is delivered through Readi, a predictive fatigue platform used across mining and fleet operations globally. Readi models fatigue risk based on sleep patterns over several days and planned work schedules, giving supervisors a forward-looking view rather than a rearview mirror.

.png?width=816&height=527&name=How%20Our%20Machine%20Learning%20Predicts%20Fatigue%20Graphic-%20816x527%20px%20(2).png)

Fatigue Science explains that predictive fatigue modelling helps remove guesswork by relying on science rather than personal judgment.

Moving Beyond Wearables in Mining Environments

Early fatigue programs often relied on wearable devices. While wearables can be useful in some situations, they introduce challenges in mining environments:

-

Devices can be damaged in harsh conditions

-

Adoption is difficult across large workforces

-

Workers may forget or avoid wearing devices

-

Hardware can create friction or privacy concerns

Because of this, many mining companies are now looking for non-wearable approaches to fatigue management in mining.

Readi was designed with these realities in mind. Instead of tracking sleep through hardware, it uses validated sleep questionnaires combined with AI and large-scale historical data to model fatigue risk. This makes the system easier to scale and easier for workers to accept.

Fatigue Science explains that modelling fatigue risk using sleep patterns over several days, without a wearable fatigue monitoring system, can be both accurate and practical at site scale.

A Layered Safety Model Works Best

Predictive fatigue insight does not replace reactive systems—it strengthens them.

When fatigue risk is addressed earlier:

-

Fewer fatigued workers enter high-risk tasks

-

Camera systems trigger fewer false alarms

-

Supervisors have context, not just alerts

-

Interventions feel preventative rather than punitive

This is described as a layered approach, where predictive insight helps prevent risk and reactive systems remain the last line of defence.

From Compliance to Safety Leadership

One of the most important changes happening today is cultural.

Fatigue management in mining is moving beyond a compliance exercise and becoming a leadership capability. Supervisors are gaining early-warning signals similar to those they already rely on for geotechnical, mechanical, or environmental risks.

This approach supports better decisions, stronger trust with crews, and a safety culture focused on prevention rather than blame.

The Future of Fatigue Management in Mining

Mining has always improved safety by adopting better evidence and better tools. Fatigue is no different.

As discussed in International Mining, the future of fatigue management in mining is being shaped by:

-

Leading indicators instead of lagging ones

-

Prediction alongside detection

-

Organizational readiness instead of individual guesswork

Fatigue Science believes that while wearables helped the industry understand fatigue in its early stages, predictive, scalable, non-wearable tools will play a growing role in the future of mining safety.

FAQ

What is fatigue management in mining?

Fatigue management in mining refers to systems and practices used to identify and reduce fatigue-related risk among workers, particularly in safety-sensitive roles.

Why are mines using predictive fatigue tools?

Predictive tools help identify fatigue risk before work begins, allowing supervisors to apply controls early rather than reacting after an incident or alarm.

Do predictive fatigue systems replace cameras?

No. Predictive systems complement cameras by preventing risk upstream, while cameras remain a last line of defence.

Does Readi require wearables?

Readi is designed to work without wearables, using sleep science, schedules, and AI to model fatigue risk at scale.

Related Posts

-

Can You Predict Fatigue Risk in Mining Without Wearables? New Research on Survey-Based Deep Learning Techniques for Measuring Fatigue Says YesFatigue is one of the biggest safety and performance risks in mining operations and other heavy industries. Workers who are tired...

-

Shifting From Reactive Dash Cam Safety to a Proactive Safety StrategyDash cams are now common across trucking fleets, mine sites, and people-transport operations. They help reconstruct incidents,...

-

Why Fatigue Risk Management Is Becoming a Strategic Priority in Safety-Sensitive IndustriesFatigue has always existed in safety-sensitive industries. What has changed is how well we can see it and how quickly it can be...