Re-Thinking the Toolbox Talk: How mine sites are changing pre-shift safety briefings to use predictive fatigue data

In the mining industry, the pre-shift safety briefing is an essential ritual that goes by many names: “toolbox talk”, “pre-start meeting”, or “pre-shift briefing,” among many others worldwide.

The pre-start meeting is the place where shift supervisors discuss the tasks for the day, highlight safety precautions, and issue warnings.

At Fatigue Science, our predictive fatigue technology has recently been implemented site-wide in several dozen sites around the world, including at Newmont, Newcrest, Minsur, Marcobre, Minera Panama, and Thiess, among many more. This technology is rapidly changing how mining firms operate their pre-shift meetings, and our rapid adoption has afforded our team the opportunity to visit mines around the world and observe how these meetings are run.

When it comes to operator fatigue, many customers are eager to describe the difference in how their pre-shift briefings operated before and after the implementation of predictivity fatigue technology.

“Is anyone feeling fatigued?” – The Traditional Pre-Shift Toolbox Talk

The first thing our mining customers often mention is “the way it was before Readi”. The story is typically some variation of the following: Five to ten years ago, fatigue started to emerge as a formally recognized safety factor. Many mines implemented or updated aging Fatigue Risk Management Protocols, with the hope that fatigue could be managed better.

The motivations are clear: up to 65% of haul truck accidents are attributable in part to operator fatigue, costing millions of dollars and significant disruption to daily operators. Moreover, a lack of adequate sleep has a direct impact on overall mine productivity: studies using telematics data from haul trucks and shovels have shown a 3.2%-3.3% lower output per hour, when the same operator is fatigued vs. non-fatigued.

Prior to the adoption of predictive technology like Readi, the pre-shift briefing often played only a minor role in fatigue management.

Protocol typically would advise the supervisors to ask openly “is anyone too fatigued to safely operate?” and rarely would an operator raise their hand – leading to little action other than shrugs and shift to the next safety topic.

There are at least 3 reasons for this historical behavior:

- Lack of Objective Fatigue Data

- Legitimate Alertness Early in the Shift

- Concerns About Consequences

Let’s break each of these down.

1. Lack of Objective Data:

Unlike impairment testing for drugs or alcohol, fatigue is harder to pin down. Until the emergence of predictive fatigue technology, fatigue was treated as a purely subjective experience. Without data, it was hard to drive action. Moreover, fatigue is an inherent part of 24/7 operations – unlike drug or alcohol impairment, for which organizations have zero tolerance.

2. Legitimate Alertness Early in the Shift:

According to the mining shift supervisors our team has spoken with, perhaps the most common response to the question of “Is anyone feeling fatigued?” in pre-shift meetings is “No, I feel fine.”

While fatigue has a massive effect on mine safety, this doesn’t necessarily suggest that workers were concealing the truth about their own fatigue.

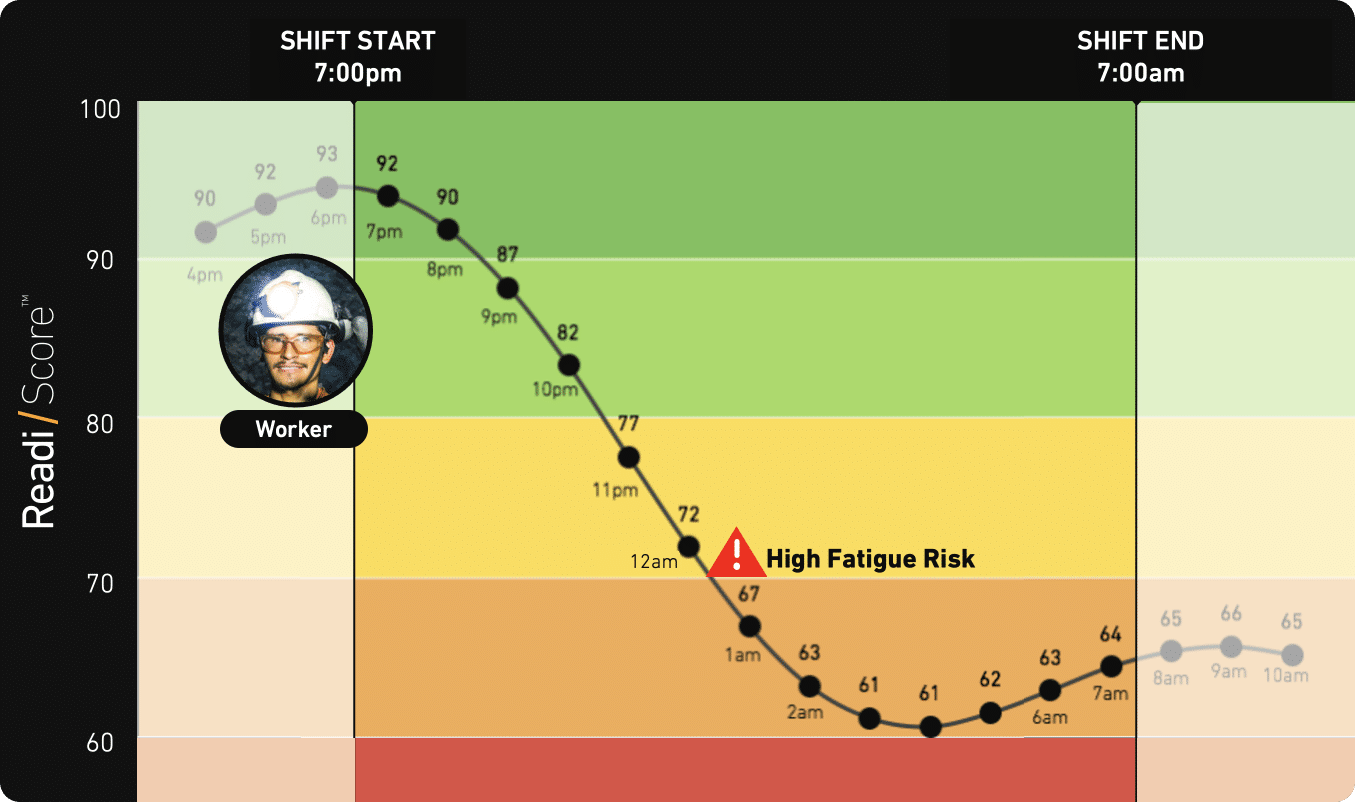

According to the science of circadian rhythms, most shifts start at a time that is close to one’s “circadian peak”. This means that while an operator may truly be facing critical fatigue at some point during their shift, they are unlikely to face it around a 7:00pm or 7:00am start time. 7:00pm, a common start time for night shifts, is, for most individuals, very close to their most alert time of day. Therefore, an inquiry into whether one is fatigued at that very moment may result in truthful responses that fatigue is not (at that exact moment) a major concern.

Fatigue is among the most insidious risks precisely because it “creeps up” later in a shift, when an operator is out in the field operating heavy equipment.

Shown below: an example of a typical fatigue progression over the hours of a fatigued operator’s night shift, as expressed by this operator’s “ReadiScore” (a validated prediction of fatigue risk)

3. Concerns About Consequences

At Fatigue Science, our team has had the chance to speak with hundreds of mine workers directly to understand their impressions of fatigue culture. As fatigue is a relatively new topic, many operators often express that – at least before the implementation of Readi – they were unsure of what would happen if they admitted to being fatigued. While fatigue management best practices dictate a non-punitive result for admitting fatigue, the ambiguity or lack of formal messaging in this regard is often a hindrance to an open culture of fatigue awareness.

How Mines Are Adapting: Predictive Fatigue Data Changes Everything

With the advent of validated predictive fatigue data, including by Fatigue Science’s industry-leading Readi platform, mining leaders worldwide are now able to overcome each of the three challenges discussed above, and are fundamentally changing the role of pre-shift meetings in fatigue risk management.

The ReadiScore is an objective, validated predictor of each operator’s personal risk of safety events and productivity loss associated with fatigue. As an hour-by-hour prediction, each operator’s ReadiScore is unique every hour and every day, creating the opportunity for a meaningful distinction in the fatigue risk level of each member of one’s crew

Consequently, leading mines today are implementing protocols that leverage predictive fatigue data in the pre-shift safety meetings. Armed with predictive fatigue data on each crew member, supervisors are now planning – on a daily basis – proactive and targeted countermeasures, hours in advance.

The approach, in effect, is strikingly simple – despite being based on a robust biomathematical model and machine learning algorithms, whose fatigue predictions have been validated with over 2.1 million hours of in-field telematics data.

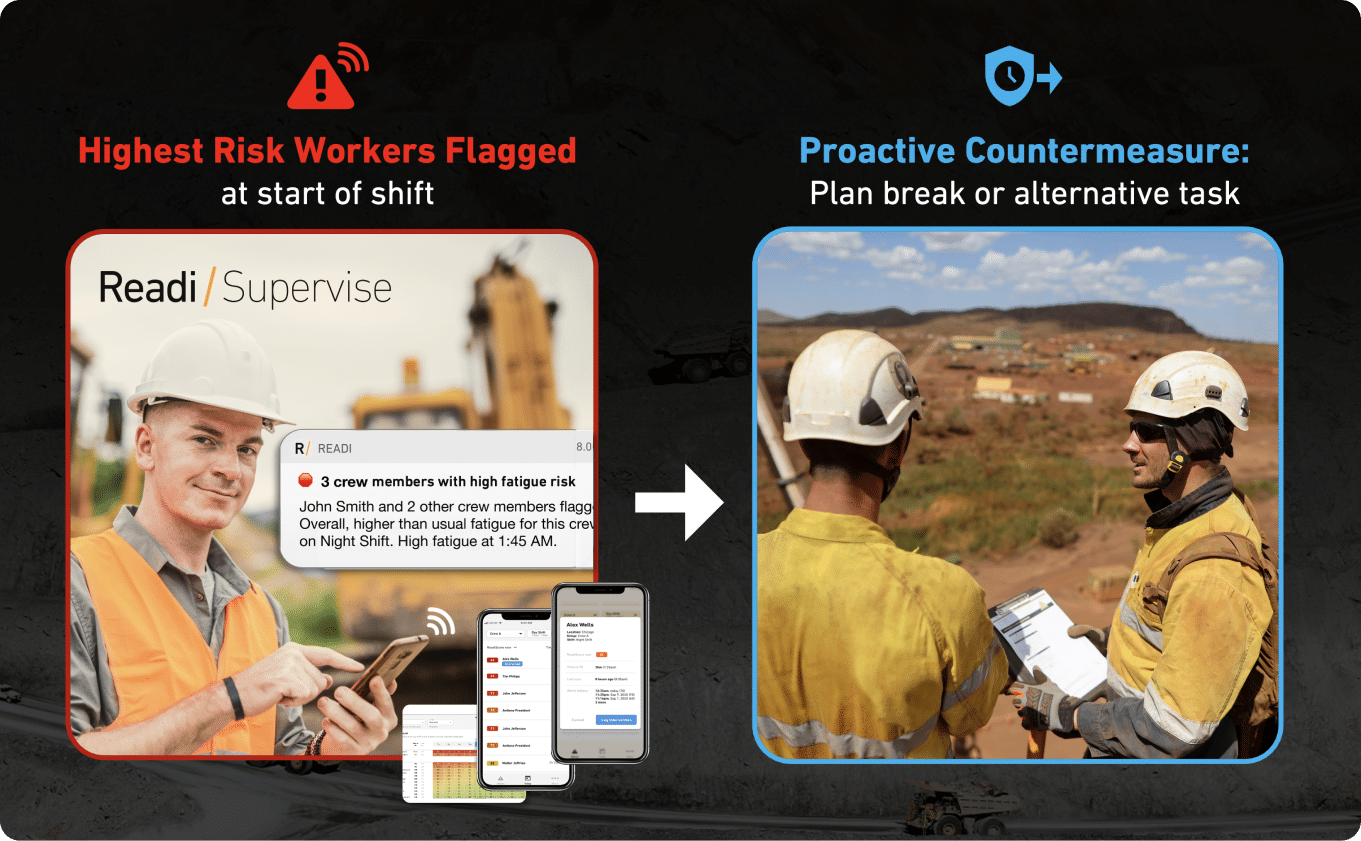

Today, at the pre-shift briefings of well over 20 leading mine sites, shift supervisors receive a simple push notification on their phones, alerting them as to whether any operators on their crew face abnormally high-levels of fatigue risk on the shift ahead.

Most importantly, these notifications are based not only on each operator’s current fatigue level, but also on their predicted fatigue level for every hour in their shift ahead. In practice, this means that an operator such as John Smith might truthfully answer “I feel fine” at the start of a shift, but at the same time be projected to face critical fatigue 6 hours later.

As an example, a notification may say, “John Smith and 2 other crew members face abnormally high fatigue levels in their upcoming shift today.”

The supervisor in a single tap can see detail on each operator, and, after consulting the operator, decide to plan simple but proactive countermeasures before the fatigue actually sets in.

These countermeasures – such as assigning an additional rest breaks – are conceptually simple but powerfully effective in practice.

In one recent study, proactive countermeasures resulted in a 50% reduction in reactive camera alarms from a Caterpillar DSS in-cab fatigue detection system. Similarly, Readi has been shown to drive an estimated 13% in lost time incidents, and an average of $6M per mine site in productivity improvements annually.

A data-driven protocol such as this also gives workers the freedom and clarity to know how fatigue is going to be managed – eliminating the fear or taboo about sharing one’s fatigue impression.

Altogether, the pre-shift safety briefing is rapidly evolving based on modern technology and predictive data – driving material safety and productivity improvements for many of the world’s leading mine sites.

If you’re interested in learning more about how your pre-shift briefings can tap into the benefits of predictive fatigue data, watch our 2-minute video or talk to one of our fatigue experts today.

or download our free eBook on the Science of Sleep for industrial workforces